Hyundai HR25T-9

|

|

|

Specifications

|

Model |

HR25T-9

|

Category Name |

Equipment

|

Year |

2024

|

|

Sale Type |

New

|

Manufacturer |

Hyundai

|

DRUM WIDTH |

1,000 mm (39.3)

|

|

ENGINE MODEL |

Deutz D 2011 L2 I

|

ENGINE POWER |

23 kW at 31 hp

|

TRAVEL SPEED |

0-9 km/h

|

|

FUEL CAPACITY |

50 L

|

SPRINKLER CAPACITY |

210 L

|

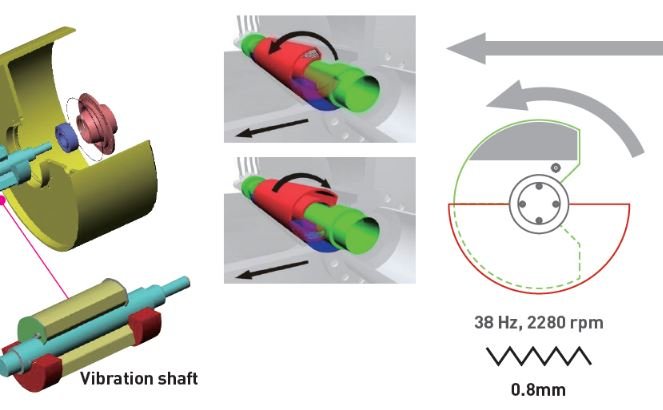

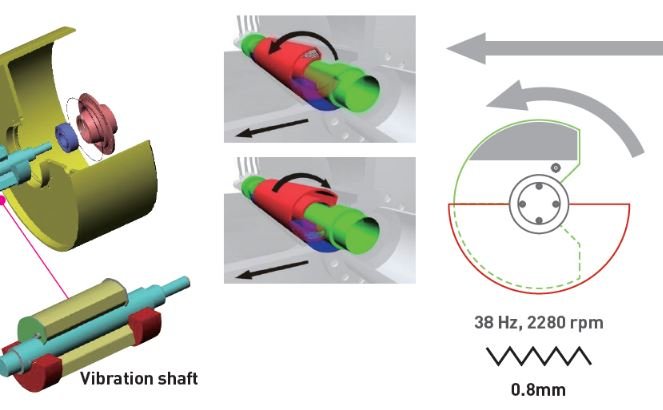

AMPLITUDE (HIGH/LOW) |

0.5 mm

|

|

FREQUENCY (HIGH/LOW) |

53/61 HZ

|

OPERATING WEIGHT (ROPS) |

2,700 kg (5,952 lbs)

|

AVERAGE LINEAR DRUM LOAD |

13.50 kg/cm

|

|

CENTRIFUGAL FORCE (HIGH/LOW) |

21.5/28 kN

|

Price |

Contact for price CAD

|

|

|

|

|

Description

|

All Hyundai Series 9 compaction roller models are designed with serviceability in mind. Engines and other components are easily accessible, thanks to the wide opening engine hood that provides 270-degree, front and side access. While the Hyundai HR25T-9 tandem-drum roller model is primarily designed for aggregate paving applications and is powered by a highly fuel-efficient and reliable Deutz diesel engine.

|

|

|

|

KEY FEATURES

|

KEY_FEATURES

STANDARD FEATURES

Performance

Engine- Deutz D 2011 L2 i (Tier 2)

Biggest Drum in Weight Class

Water Spray System

Hydrostatic Drive

Convenience

Adjustable Steering wheel

Noise and bearings

Console Lever

Laterally slideable seat

Serviceability

Easy Accessible Battery

Easy air filter replacements

Conveniently layered lines

Maintenance-free articulated joint

|

OPTIONAL FEATURES

Back up alarm

Rotating beacon

Edge Cutting and pad roller

Environmentally friendly hydraulic fluid

|

|

|

RELIABILITY AND DURABILITY

|

RELIABILITY_&_DURABILITY

RELIABILITY RELIABILITY

Hyundai construction equipment is precision designed with trusted and proven components and systems from leading OEM’s. Hyundai rollers are designed to be rugged and reliable for longer up time, reduced operating cost and improved productivity.

|

DURABILITY DURABILITY

Hyundai construction equipment is manufactured with the highest grade of steel due to Hyundai’s dominance in the steel and shipbuilding industries. Rigid cycle testing, heat testing, vibration testing and shock load testing is conducted in the design and manufacturing process of all new models insuring optimum durability and reliability.

|

|

|

INDUSTRIES

|

|

|

|

WHAT CUSTOMERS SAY

|

|

|

|

PERFORMANCE

|

|

|

|

CONVENIENCE

|

CONVENIENCE

ADJUSTABLE STEERING WHEEL

The steering wheel can be adjusted to fit the operators needs which will allow them to be more comfortable while working.

|

NOISE & BEARINGS

A minimized noise level is attained by means of special engine bearings.

|

CONSOLE LEVER

The console lever provides you easy control of the functions related to working with the tandem roller, which are activated by the selector switches, vibration on the dashboard, and the joystick lever.

|

LATERALLY SLIDEABLE SEAT

The operator's seat is laterally adjustable for optimal visibility on either side of the roller when compacting against an edge.

|

|

|

SERVICEABILITY

|

SERVICEABILITY

EASY ACCESSIBLE BATTERY

Easy open compartment allows for quick battery replacement.

|

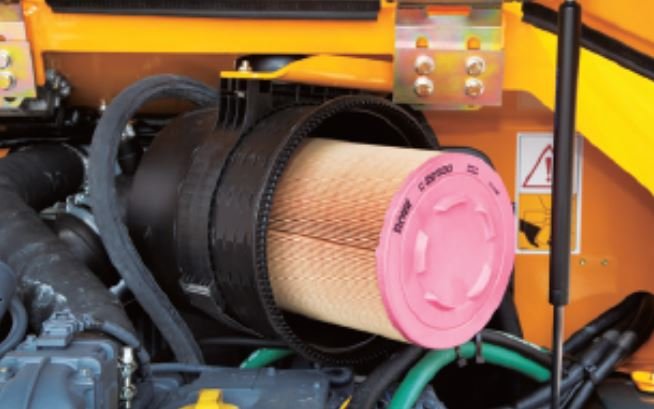

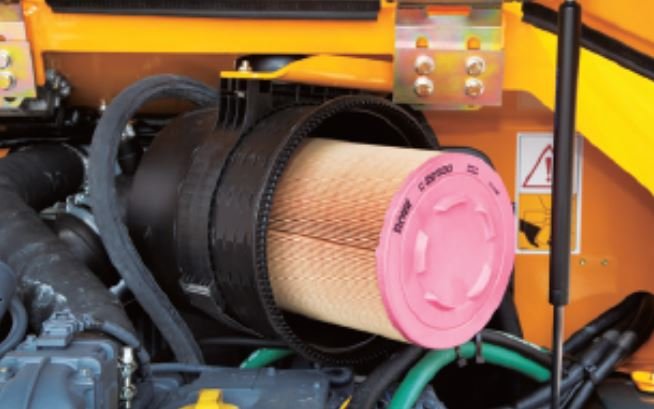

EASY AIR FILTER REPLACEMENTS

Once the hood is open, it is very easy to remove and replace the engine air filter.

|

CONVENIENTLY LAYERED LINES

All maintenance components and aggregates are easily accessible, thanks to the wide opening of the engine hood.

|

MAINTENANCE-FREE ARTICULATED JOINT

The articulated pendulum joint requires little maintenance, thanks to the Teflon® bearing seats. No lubrication points at the machines.

|

|

|

SAFETY

|

SAFETY

EXCELLENT VISIBILITY

The compact dimensions ensure a good view of the machine itself and its surroundings and allow for operation on small and narrow construction sites.

|

ROPS FOLD-ABLE YOKE

The ROPS foldable yoke is available for driver’s safety and easy transportation.

|

ECO MODE VIBRATION DRIVE

ECO speed enables the driver to reduce the rotational speed of the Diesel engine to the ideal engine torque and the pump for the hydrostatic drive of the vibration unit establishes the required rotational speed of the exciter shaft by adjusting the volumetric current.

|

BACKUP ALARM

The backup alarm provides an audible warning for workers on the jobsite when the roller is moving in reverse.

|

|

|

LITERATURE

|

|

|

RELIABILITY

RELIABILITY DURABILITY

DURABILITY

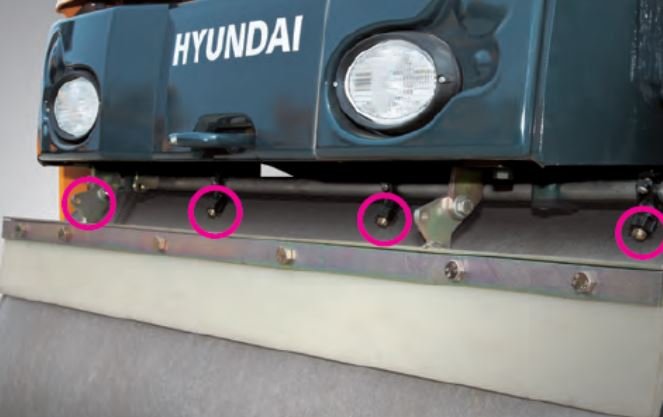

WATER SPRAY SYSTEM

WATER SPRAY SYSTEM