| AF225 |

AF230 |

AF236 |

AF240 |

AF245 |

AF250 |

| Width |

25' (7.6 m) |

30′ (9.1 m) |

36′ (10.9 m) |

40′ (12.2 m) |

45′ (13.7 m) |

50′ (15.2 m) |

| Operating weight (incl. reel) |

6,769 lbs

(3,070 kg) |

7,398 lbs

(3,356 kg) |

7,912 lbs

(3,589 kg) |

8,660 lbs

(3,928 kg) |

8,990 lbs

(4,078 kg) |

9,226 lbs

(4,185 kg) |

| Hydraulic System |

Hydraulics are limited to the combine reel circuits only |

| Cutting System |

Honey Bee cutting system with SCH sections |

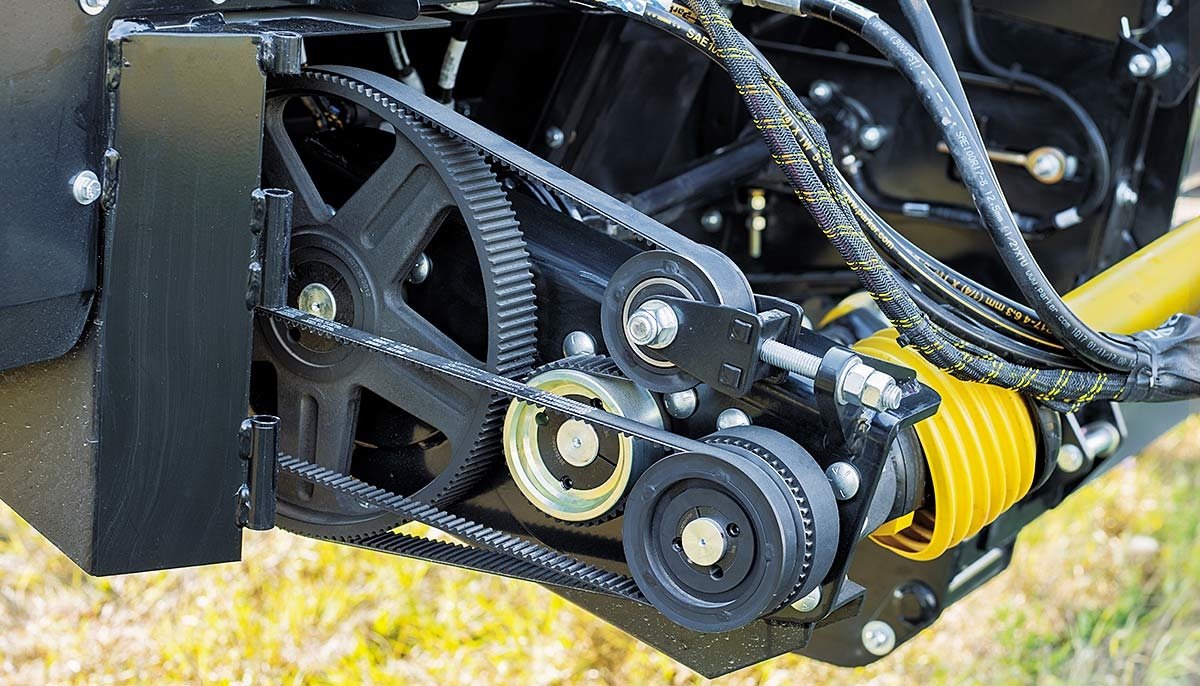

| Knife Drive |

Fully synchronized mechanical knife drive |

| Draper |

New high performance tensioning system and mechanical drive |

| Center Deck |

New high performance tensioning system and mechanical drive |

| HB Draper Shield |

Patented crop flow assistance device (Optional) |

| Cross Auger |

Crop flow assistance device (optional) |

| HB Reel |

High strength, high performance reel with multiple crop settings and finger spacing options |

| Reel Drive |

Centre hydraulic reel drive |

| Transport System |

Heavy-duty road transport with electric brakes (Optional RV/AG plugs) |

| Tires / Wheels / Hubs / Spindles |

Standard |

| Cutterbar Poly Skid |

Standard with sectional panels |

| Combine Adapters |

Available for most models of self-propelled combines |

| Fore/Aft |

Standard – using combine functions |

| Automatic Reel Speed Control |

Standard equipment – combine must have reel speed circuit |

| Gauge Wheels |

Standard |

| Subframe Suspension |

Standard |

| Header Height |

Standard – combine needs header height function |

| Automatix |

Standard |

| Operating Modes |

Standard – flex and rigid |

| Reversible Mechanical Drive |

Standard |

| Maintenance Requirements |

4 x 10 hour knife grease / 15 x 50 hour drive-line grease |

| Flex |

A total of 9″ flex in cutterbar |

| Cutterbar |

Independently suspended |

| Air System |

Standard on-board air compressor with cab controls (AUTOMATIX) |

| HB Vertical Shears |

Powered by mechanical knife drive (optional) |