|

Features and options

1. Capacity 695 pi3 à 897 pi3.

2. Reinforced tub fl oor provides longevity of the tub and also to the load cells by equalizing the weight uniformly.

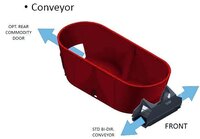

3. TRI-CUT™, auger with 2-position adjustable and reversible knives (10 standard) and 2 sweeping dispensers ensuring a 30% faster and more consistent discharge.

4. Discharge options: Side trap or front conveyor.

5. Carbide treated self-sharpening tungsten knives.

6. Industry’s fi rst hydraulic TRUE-CUT™ restrictor blades allows the operator to engage and disengage during the mixing process preventing all risks of overprocessing feed.

7. The DG500 indicator is a universal, programmable weighing indicator for recipes, dispensing and data storage. It guarantees an extremely precise weighing thanks to the protected load cells and strategically located under the tank. Compatible with the DTM suite.

8. 4-point scale system.

9. Rolled side walls (not bent) for better fl ow of material, avoiding restriction around auger and naturally increased sturdiness.

10. SMART CONTROL remote control (optional) provides you full wireless control to: customize weighing system and recipe, hydraulics, speed of belt etc.

|