kverneland

ID # 16827510

Kverneland Exacta CL EW

Call for Price

Overview

Specifications

Documents

|

Spreading the Easy Way!

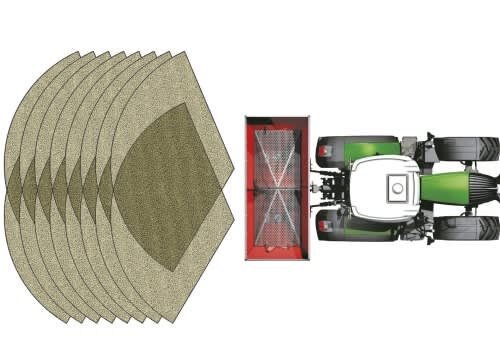

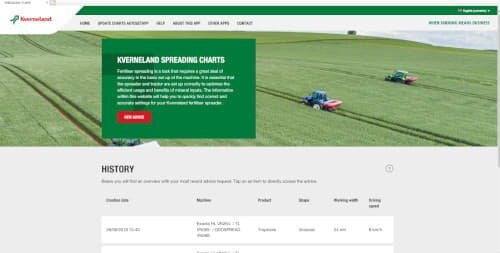

The Kverneland Exacta CL EW is the ideal weighing spreader for the smaller grower! This ISOBUS compatible weighing spreader is equipped with a unique reference sensor, which will correct automatically on slopes and for shocks. Therefore this spreader can work with high accuracy on rough terrains and in hilly conditions. Speed related spreading, with auto calibration, will help to prevent over and under dosing which will result in better yields and saving of fertilizer. For even more comfort, it is possible to use the spreader in combination with GPS. With GPS controlled spreading the Kverneland Exacta CL EW spreader has 2 sections and automatic start/stop on headlands based on the GEOPOINT. It is even possible to do variable rate spreading according to application maps. The Exacta CL EW can be operated with the IsoMatch Tellus GO, IsoMatch Tellus PRO or any ISOBUS compatible tractor terminal. Highest accuracy in all conditions: even spreading quality guaranteed! Save costs and increase quality: spreading the Easy Way! | ||||||||||||||||||||||||||||||||

|

The Advantages: | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

|

Highlights | ||||||||||||||||||||||||||||||||

|

Model

Exacta CL EW

Category Name

Agriculture

Year

2021

Sale Type

New

Manufacturer

Kverneland

Documents

Model

Exacta CL EW

Category Name

Agriculture

Year

2021

Sale Type

New

Manufacturer

Kverneland

Quantity

0

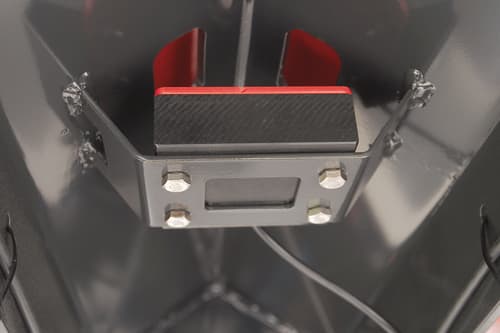

Weighing System

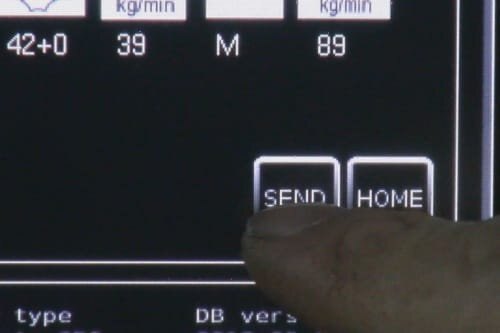

Weighing System EasySet: Easy Setting and Adjustment

EasySet: Easy Setting and Adjustment Border Spreading

Border Spreading ISOBUS Control

ISOBUS Control