kverneland

Kverneland PN - RN

Cost efficient, easy to adjust and to maintain

The PN/RN models are robust semi-mounted reversible ploughs with a centre-mounted wheel and manual stepwise furrow width adjustment.

The up-graded models are delivered from June 2016 as follows:

Robust plough constructed around a robust 200x200 mm induction heat treated frame.

In-Furrow & On-Land operations

The advantages

1- unique Kverneland steels and heat treatment technology to the complete plough for best durability

2- center mounted wheel for easy ploughing out to fences, hedges...

3- safe and smooth reversal of the plough ensured by turnover mechanism being linked to the wheel assembly

4- unique headstock for minimum turning circle. Cat. III or IV

5- gentle movement between the turnover arm and the frame via plastic wear plates. No lubrification needed. Less noise too

6- easy adjustment of the wheel angle when changing the ploughing width, via a turnbuckle

7- optional hydraulic front furrow width adjustment for In-Furrow models

8- large clearance

9- unrivalled Kverneland Auto-reset system for non stop ploughing for PN. No maintenance. Shearbolt protections for RN

10- extendable by 1 furrow to the maximum number of furrows indicated in the chart below

In-Furrow & On-Land operations

Any PN/RN ploughs ordered from the 1st of June 2016 can work both In-Furrow and On-Land. Adjustments between In-Furrow and On-Land and vice-versa are hydraulic:

// On-Land models can also plough In-Furrow

// In-Furrow models can be retrofitted with an On-Land Kit

On-Land models suit tractors with up to 3,60 m outer wheel/track width.

Technical Specifications:

| Model | Interbody clearance cm | Under beam clearance cm | No of forrows | Working width cm |

| PN | 100 | 70/75 | 5 - 9 | 35 - 40 - 45 |

| PN | 115 | 70/75 | 5 - 7 | 40 - 45 |

| RN | 100 | 70/80 | 5 - 9 | 35 - 40 - 45 |

| RN | 115 | 70/80 | 5 - 7 | 40 - 45 |

|

Leg protections

|

|

|

|

Main Frame |

Stronger but not heavier

Long lasting

Frame availability

Available as:

|

|

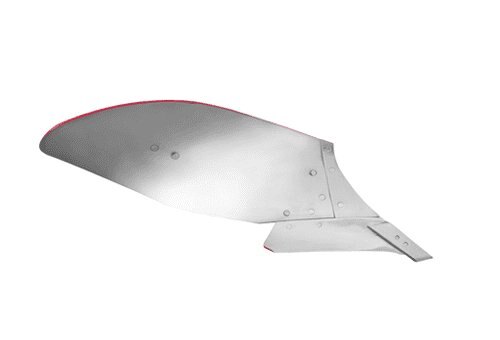

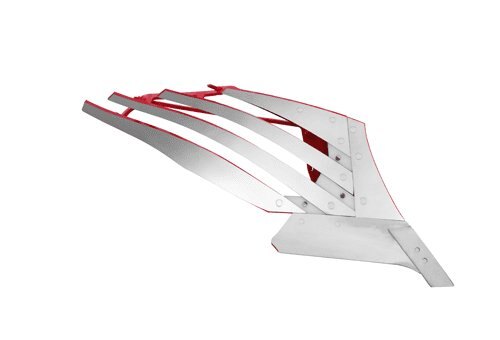

Selection Bodies |

|

Excellent Ploughing Quality They are renowned all over the world for their:

Bodies of a unique steel. Kverneland Technology: 12 hours carburising heat treatment process for:

Body No. 8 – “Universal body” or light to heavy soils

Body No. 9 – “Deep Universal body”

Body No. 28 – “Wide tyre body”

Body No. 30 – “Finger body”

Body No. 34 – Plastic mouldboard

Body No. 38

|

|

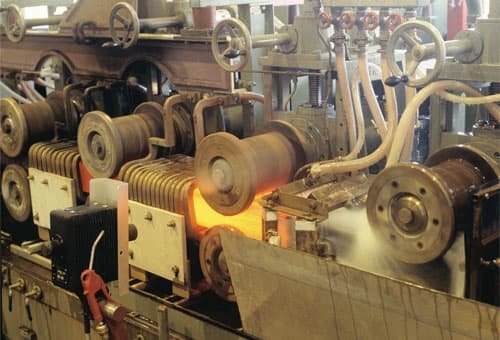

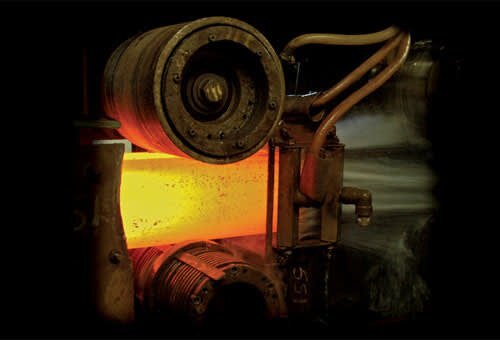

Heat Treatment |

|

Kverneland Heat Treatment Technology:

|

|

Vibromat System |

|

Eliminates Vibrations in the Harshest Conditions Kverneland is the first company to find a clever and simple solution. The Vibromat is a very efficient shock absorber working like a car shock absorber. Available for LD and RN ploughs (mechanical furrow width adjustment) Advantages:

|