kverneland

Kverneland 150 S

Ideal choice for stony conditions

Light and robust plough: Kverneland Technology!

Launched in 2011, this new mounted reversible plough aims at intensive ploughing for small to medium size farms.

The new design of the 150 serie induces low operating costs to the farmer while guaranteeing Kverneland’s values: high performance, long working life even in the toughest of soil conditions

150x150mm induction heat treated frame to the same standards as all Kverneland ploughs. New 150 serie head stock with a heat treated 110mm Ø main shaft.

Recommended for tractors up to 150 HP.

The advantages

1- low lift requirements, easy to pull

2- easy to adjust and to operate: 1rst furrow adjustment via the parallelogram system automatically corrects the alignment of the plough

3- adapts easily to different tractors and wheel settings

4- hydraulic front furrow adjustment and hydraulic alignment of the frame are also available

5- unrivalled Auto-reset system for non stop ploughing. Bodies release independently to one to another. No maintenance!

6- stepwise adjustable working width: 30 to 50cm (12”-20”)

7- choice of cross shaft, category II and III or quick coupling option.

8- wide range of accessories

9- 3 to 5 furrows, extendable by 1 f. (max. 5 furrow plough)

New Naming System (2009):

// Kverneland: Brand

// 150 = 3 digits = reversible ploughs

// Reversible Semi Mounted 650,750,850 for more efficiency

// Only 2 digits for simpler Conventional ploughs

// S: stands for Springs (Leaf Spring Kverneland Auto-reset system)

// B: stand for Bolts (=shear Bolts)

Technical Specifications:

| Model | Interbody clearance cm | Head stock | Type of beam | Under beam clearance cm | Working width cm | No of furrows |

| 150 S | 85/100 | 150 | Auto-reset | 70/75 | 30 - 50 | 3 - 5 |

|

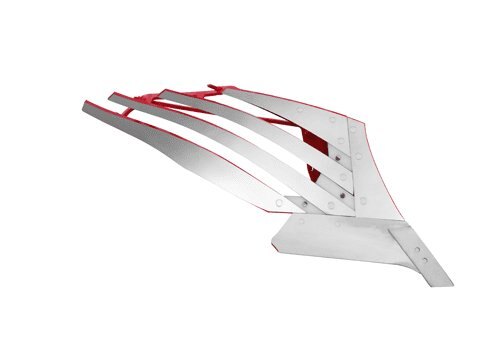

Leg protections

|

|

|

|

Main Frame |

Stronger but not heavier

Long lasting

Frame availability

|

|

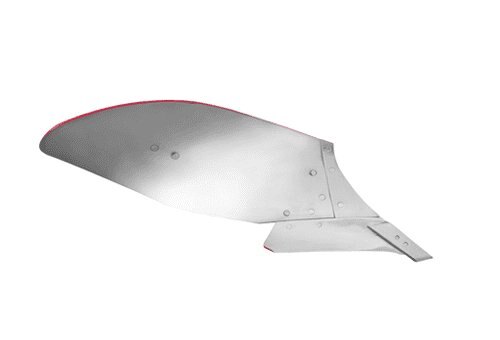

Selection Bodies |

|

Excellent Ploughing Quality They are renowned all over the world for their:

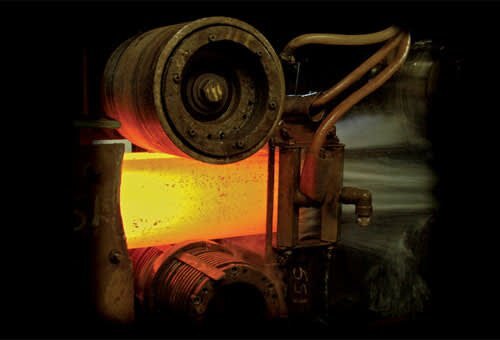

Bodies of a unique steel. Kverneland Technology: 12 hours carburising heat treatment process for:

Body No. 8 – “Universal body” or light to heavy soils

Body No. 9 – “Deep Universal body”

Body No. 28 – “Wide tyre body”

Body No. 30 – “Finger body”

Body No. 34 – Plastic mouldboard

Body No. 38

|

|

Heat Treatment |

|

Kverneland Heat Treatment Technology:

|