kverneland

Kverneland 3300 S

The ideal plough for all conditions

Robust plough, lighter than competitors'. Easy to lift and to pull. Designed for any soil conditions. Maximise ploughing thanks to the Variomat and feel safe in transport (Kverneland Trailer Transport Solution "TTS")

The Kverneland 3300 S is available from 4 to 6 furrows with a 120 X 200 mm main frame (no welding) and the headstock No 300. Cat. III/IV.

Advantages

1- unrivalled Kverneland Auto-reset system for high quality ploughing in tough conditions. No maintenance. Quick adjustment of releasing forces: unscrew 2 bolts

2- Kverneland steels and heat treatments for the complete plough ensure trouble free working conditions and the highest second hand market value.

3- Variomat, Vari-Width® system for easy On the Move working width adjustments. Optimise soil conditions, output and tractor fuel consumption.

4- automatic pulling line adjustment (Auto-line) for high performance ploughing and low wear of parts

5- optional automatic front furrow adjustment. Mechanical front furrow adjustment is standard

6- unique memory system that maintain desired furrow width settings after the reversing cycle

7- Safe transport: Kverneland Trailer Transport Solution (optional)

8- Aero-profile legs for best soil flow performance

9- Quick central adjustments of skimmers for the perfect ploughing

10- Efficient: re-consolidate in one pass: Packomat, Kverneland packers and packer arm compatible

11- wide range of accessories

Technical Specifications:

| Model | Interbody clearance cm | Head stock | Type of beam | Under beam clearance cm | Working width cm | No of furrows |

| 3400 S Variomat | 85 | No 300 | Auto-reset | 80 | 30 - 50 | 4- 6 |

| 3400 S Variomat | 100 | No 300 | . | 80 | 35 - 55 | 4- 6 |

|

Innovations

| ||||||||||||||

|

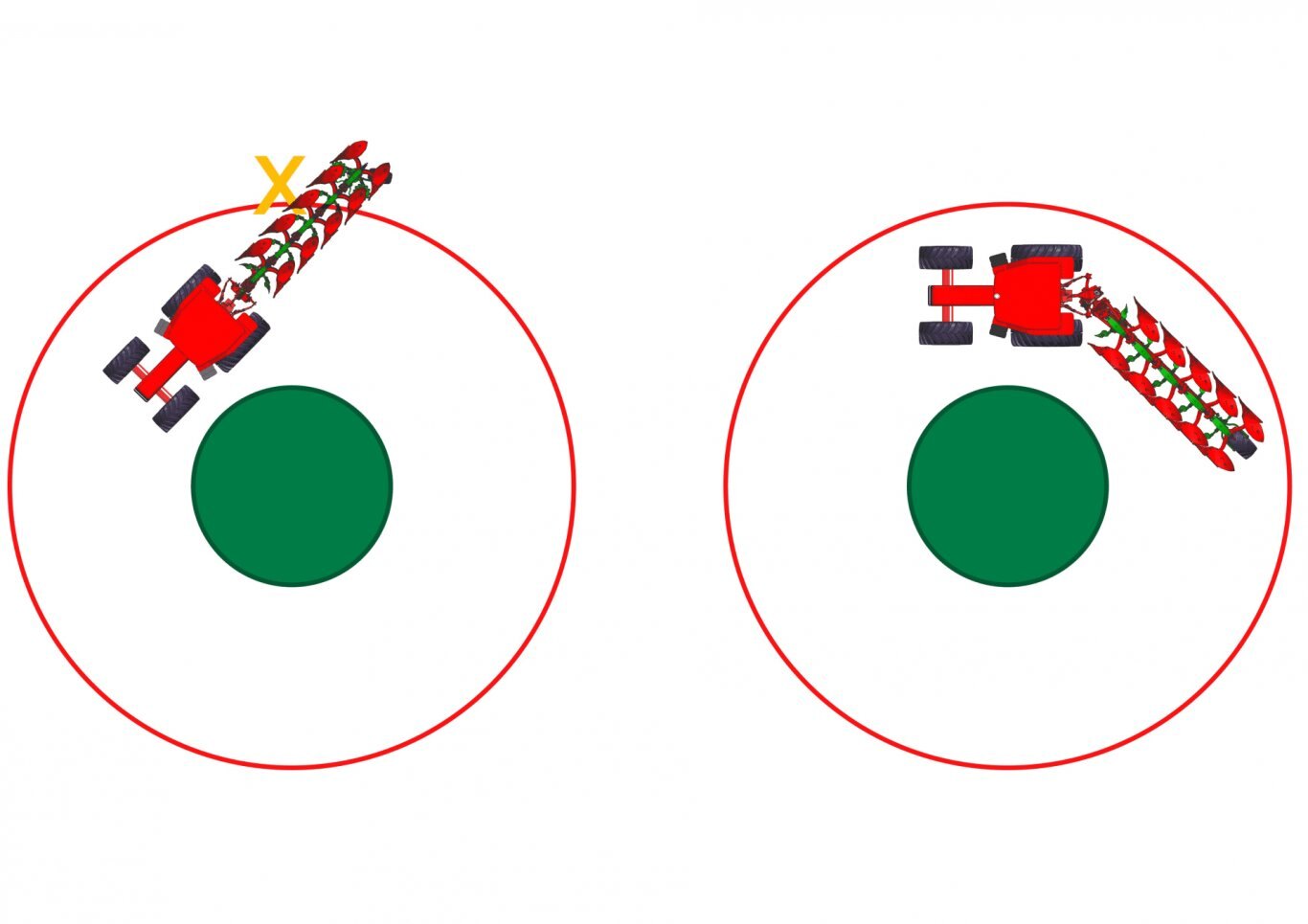

// The plough behaves like a trailer. Turnable cross shaft max. 45° mutual offset during transport. // Safe: maximum security for anything/anyone around and for the driver. No tilting out when driving in curves. // Easy conversion from transport to ploughing. // The Kverneland TTS is an option

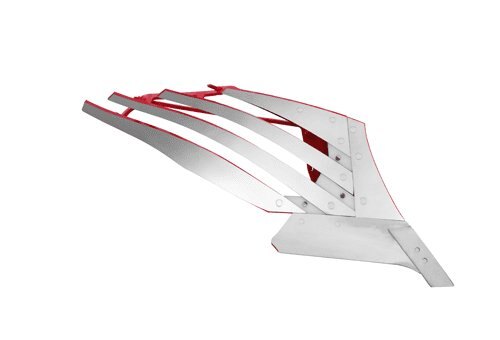

// Special design for best soil flow. // 80 cm leg height to prevent potential blockage in heavy residues, manure, cover crops or when ploughing deeper. // Robust legs: pre-shaped components limiting weldings. // Low pulling requirement and hence fuel consumption thanks to low weight hollow legs.

// Unrivalled Kverneland mechanical leaf spring system for Non-stop ploughing. // No Maintenance. // Legs, plough and tractor lives are protected and lengthened. // Quality ploughing: legs release independently one from another and come back to the correct position. // Easy adjustment of releasing forces: unscrew 2 bolts to add or remove springs.

// Smart skimmers adjustment // Unique: central adjustment of skimmers working depth. // Quick operations: right and left skimmers adjust simultaneously. // High ploughing performance: the correct adjustment of skimmers contribute to a quality ploughing. // Disc coulters also available: plain or notched (18”/45cm or 20”/50cm) |

|

Main Frame |

Stronger but not heavier

Long lasting

|

|

Variomat system |

|

Benefits: // Easy variation of ploughing capacity // Perfect match at all time between tractor capacity, implement and soil conditions // Time saving: up to 30% more capacity // Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity // Better work: plough up to the hedges, fences, trees and ditches // Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section // Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear. |

|

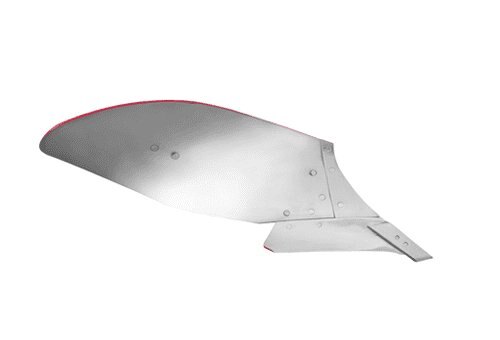

Selection Bodies |

|

Excellent Ploughing Quality They are renowned all over the world for their:

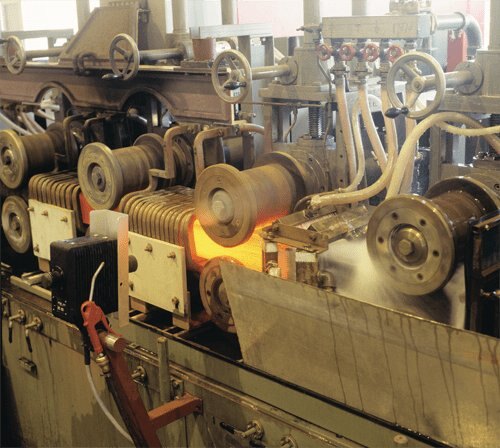

Bodies of a unique steel. Kverneland Technology: 12 hours carburising heat treatment process for:

Body No. 8 – “Universal body” or light to heavy soils

Body No. 9 – “Deep Universal body”

Body No. 28 – “Wide tyre body”

Body No. 30 – “Finger body”

Body No. 34 – Plastic mouldboard

Body No. 38

|

|

Heat Treatment |

|

Kverneland Heat Treatment Technology:

|

Aero-profile legs

Aero-profile legs Auto-reset system

Auto-reset system