Snowex

SnowEx® 11780

ADVANCED SALT DELIVERYForget everything you thought you knew about poly spreaders. Available in capacities from 1.5 to 5.0 cu yd, the HELIXX Poly Hopper Spreaders are a from-the-ground-up design based on extensive testing and three decades of SnowEx® hopper spreader innovation. The exclusive material delivery system vastly outperforms traditional augers, delivering unmatched material flow. |

|

|

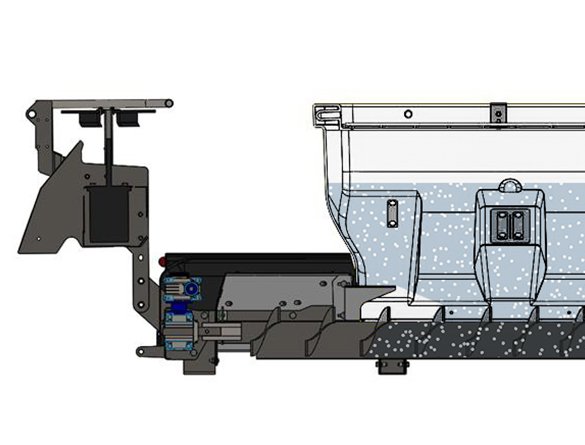

FULL LENGTH HELIXX AND MULTI-DIMENSIONAL TUBThe HELIXX runs the entire length of the hopper with variable flights. Combined with strategically positioned ribs/angles within the poly tub walls, this promotes the best possible material flow and even unloading. |

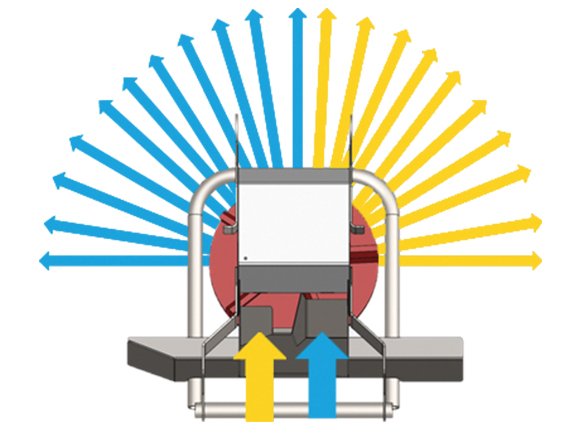

TRIPLE THREATSpread, pre-wet or spray with one machine. By adding pre-wet tanks, a pump and a spray kit, the HELIXX spreaders not only pre-wet materials, but they can also be used for spraying liquid brine directly onto the driving surface for anti-icing applications. The components offer a simple plug-and-play installation, meaning a contractor can upgrade to pre-wetting or direct liquid applications at any time. |

|

|

MATERIAL LEAK/SPILL PREVENTIONThe HELIXX extends beyond the hopper and into the patented pre-wet mixing chamber to help prevent leaking/spilling during transport while providing an ideal location for pre-wetting material. |

STAINLESS STEEL FRAMEConstructed of corrosion-resistant stainless steel, the frame features a unique leg and sill design to form a ridged backbone structure for greater durability. |

CHUTE BAFFLE SYSTEMBaffles within the chute direct material to key areas on the spinner resulting in a remarkably even and consistent spread pattern, as well as reducing material directed back at the vehicle. |

SPINNER HEIGHT ADJUSTMENTThree spinner height adjustments allow spreaders to achieve a consistent spinner height of 18 to 22 inches off the ground, regardless of vehicle type (Standard on 11800 and 11810 models). |

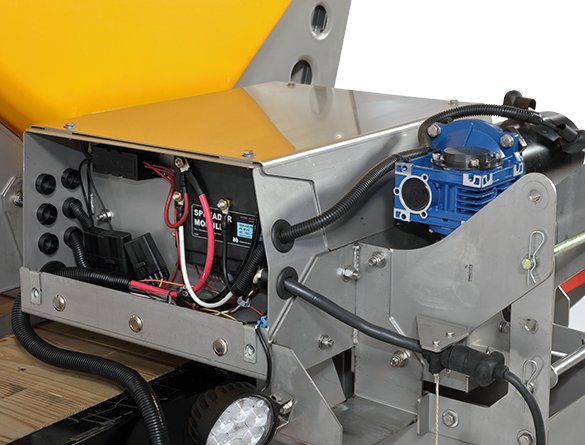

DUAL VARIABLE-SPEED CONTROLAllows for variable control of spinner and HELIXX system speeds for precise material delivery, whether at low or high output. Features auto reverse and integrates with accessories (including pre-wet and direct liquid application). |

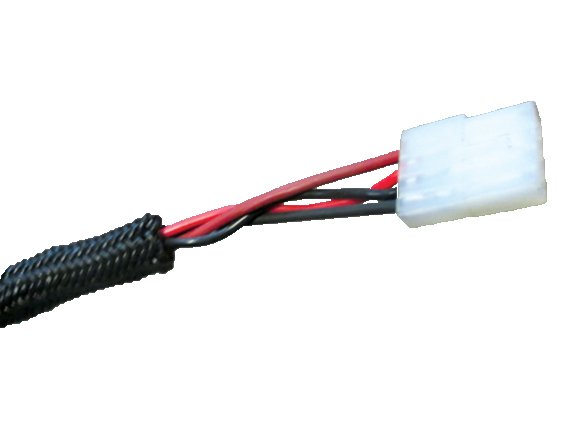

SIMPLE INSTALLATIONOnly requires a single 4-pin wire routed into the cab to install the compact control. |

FLEET FLEXThe FLEET FLEX electrical system provides a consistent electrical platform and complete fleet interchangeability between all HELIXX spreaders. |

NO-BLAST STARTUPFor maximum material placement and control, the spinner doesn’t blast upon startup, instead starting at the desired speed setting on the dial. |

FLIP-UP/REMOVABLE CHUTERemove a single pin to flip-up the chute, or two pins to take it off entirely, for easy hitch access and more flexible storage. |

|

REAR-MOUNTED GEAR BOXEasy access to motors, drives and other key components maximizes serviceability. |

WORK LIGHTOffers better visibility at rear of spreader during night applications. |

VIBRATORAttached to structural cross member, it vibrates the entire unit (tub and sill) to maximize flow of bulk materials. |

TOP SCREENTop screen ensures material that enters the hopper is consistent size by breaking up any large clumps and filters out large debris to ensure proper operation. |

FITTED TARPA tarp fitted to the spreader’s dimensions protects material from outside weather elements and keeps it dry. |

FORK POCKETSFor simple install and removal, fork pockets are integrated into the frame legs. |

| Name | Link |

| Snowplows Brochure | Download |

DUMP SWITCH

DUMP SWITCH