Built Tough for Commercial and On-Farm Application

A Better Applicator through Better Design

Whether you’re seeding or applying herbicide, a Salford Valmar 246 Pull-Type Granular Applicator is designed to deliver unparalleled accuracy under a wide variety of ground conditions. Its rugged construction is sturdy enough to withstand the rigors of commercial use, making it the right choice for a rental fleet, custom applicator, or a farm operation. Moreover, the 246 incorporates a number of innovative features designed to make material application easier, safer and more precise than ever before.

Exceptionally Accurate Metering System

The 246 applicator achieves its accuracy, thanks to a ground-driven metering system that ensures the precise application rate regardless of ground speed. As with most Valmar units, the 246 uses our 60-speed gearbox that allows the application rates in increments of five percent. Drive ratio changes are made at the gearbox, eliminating the need to move chains and realign sprockets. For cropping conditions that require a rate change on the go, an optional Alternate Rate Kit can be added to allow an instantaneous rate change on the go.

Greater, More Uniform Coverage

The 246’s wide 60-ft. boom and large 60-cu.-ft. hopper enables operators to cover more acres between fills. Equally important, the self-leveling boom ensures a uniform spread pattern, regardless of field conditions. For safety, the boom also features breakaway tips to help minimize damage that may occur from striking an obstacle in the field.

Simple Calibration

Calibrating an applicator is necessary to ensure proper flow rates, especially when determining the setting for new products, seeds or seed mixtures. The 246 applicator makes this process easier by allowing the venturi and manifold system to be dropped so that a funnel tray can be inserted for easy collection of product. Operators can use the crank handle (provided) to simulate ground travel and establish precise calibration for any product. The funnel also makes emptying the hopper an easy and safe procedure.

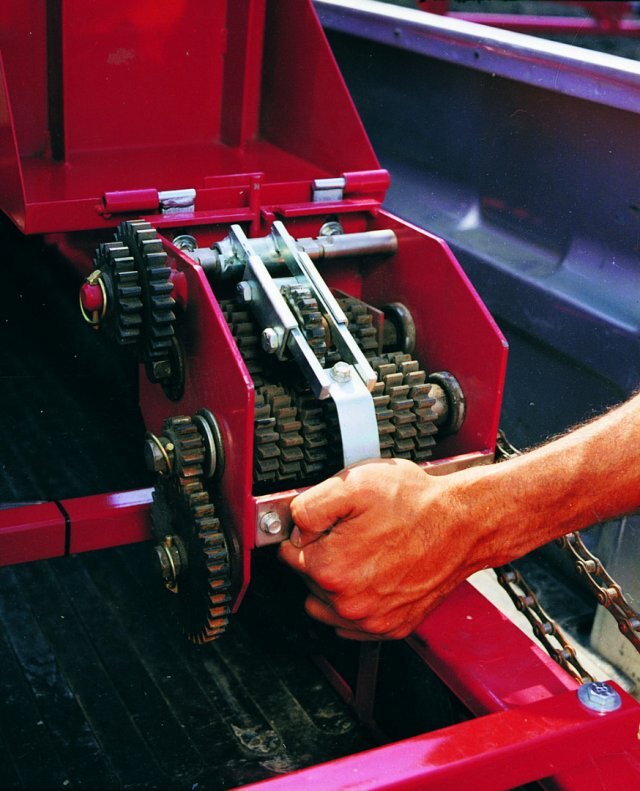

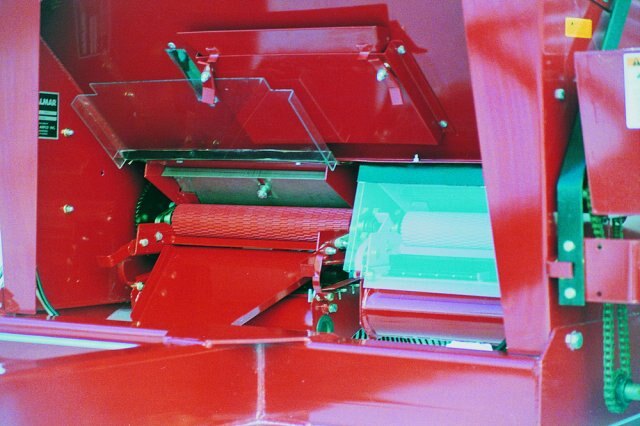

Easier Maintenance and Cleaning

The 246 applicators feature a number of innovations that make maintenance and cleaning easier. One important feature is the convenient hopper-bottom slide gates which allow the rollers to be removed for cleaning or inspection. Access to the rollers and venturi system is also easier due to moveable plexi-glass shields which protect the metering system.

Section Control The 246 has a four section shut off, half shut off on either side that allows users to effectively control the spreader for a more accurate and environmentally friendly application when we are becoming more aware of the need to control where our inputs are applied. Having this control allows users to turn off different sections in areas where fertilizer already has been applied, thus reducing waste. |