new holland

New Holland Air Disc Drills - P2185 - 40 ft

|

TOOLBAR WIDTH, FT (M) 40 FT. (12.2) AVAILABLE SPACING, IN (CM) 7.5 (19.1) & 10 (25.4) &15 (38.1) | |

ACCURATE SEED PLACEMENTPatented parallel-link opener design delivers industry-leading seed placement accuracy at higher speeds over rough terrain, resulting in best-in-class seed emergence. | |

DOUBLE SHOOT CAPABILITYThe P2082 Widths from 30 to 60 feet with 10-inch row spacing. | |

MORE ACRES PER DAYP2000 Series air disc drills are designed to operate at higher ground speeds of 7 to 8 miles per hour to cover more acres per day. | |

DURABLE CONSTRUCTIONTough Earth Metal® 18-inch disc blades, strong row-unit components and heavy-duty packers provide unrivaled durability. |

PRODUCTIVE PERFORMANCE IN THE FIELDThe P2080 disc drill model is specifically designed for P1000 Series air cart applications. It’s offered in 30-, 40-, 50- and 60-foot widths in 7.5- or 10-inch spacing for big acres and maximum productivity. The frame design offers exceptional weight distribution that is ideal for many different crops and soil types. In addition, the narrow V-shape envelope adds additional stability for safe and convenient transport to and from the field. |

PARALLEL LINK DESIGN

|

DEPTH CONTROL

|

ACCURATE SEED PLACEMENTThe accurate seed placement is ideal for small grains such as wheat, barley, rice and canola. The new scraper and opener geometry allow for consistent seeding depth across the range of operations. There is no need for a seed shelf, as the seed can be placed in the bottom of the trench. High mounting of the seed tube ensures reduced wear, long life, and reduced plugging over the competition. The 18” disc cuts cleanly through the heaviest crop residue to ensure optimal seed-to-soil contact. This ideal disc size reduces residue 'hair pinning' and maximizes seed-to-soil contact for ideal seed germination. The discs are also set at a seven-degree angle to open a uniform seed trench where the seed is accurately placed. |

CLOSING SYSTEM DESIGNED TO ACCOMMODATE VARIOUS SOIL CONDITIONS

|

VARIABLE PACKING PRESSURE RANGE ADJUSTMENT

|

IN-CAB DOWN-PRESSURE CONTROLIn-cab hydraulic down pressure adjustment is standard equipment, allowing operators to make on-the-go adjustments without leaving the seat by using the IntelliView™ IV display. Three convenient presets help maintain ideal row-unit down pressure for changing field conditions. |

SECTIONAL CONTROL

|

UNMATCHED DURABILITY COMBINED WITH REDUCED MAINTENANCE COSTS

|

FRAME ACCESSIBILITY

|

BEST WING FLEX IN THE INDUSTRYThe P2000 series disc drill offers the best wing flex in the industry. Its flexible frame provides a total of 25° total flex – 10° flex up and 15° flex down. This feature allows for consistent accurate seeding placement across the width of the drill. Flexibility also disperses frame stress for more durability than traditional welded joints. Where the frame flexes, durable, self-lubricating joints with chrome pins and polyurethane pads add lasting performance unmatched in the industry. |

PRECISE PLACEMENT OF SEED AND FERTILIZER IN ONE PASS FOR EARLY, UNIFORM EMERGENCEThe P2082 double-shoot air disc drill is designed for one-pass placement of seed and fertilizer with accuracy for uniform emergence, better stands, higher yields and more profit for you. Choose from seeding widths of 30, 40, 50 and 60 feet with available 10-inch row spacing. |

SEPARATE, FIXED PLACEMENT ZONES FOR SEED AND FERTILIZER

|

CUT THROUGH TOUGH RESIDUE WITH REDUCED HAIR-PINNING

|

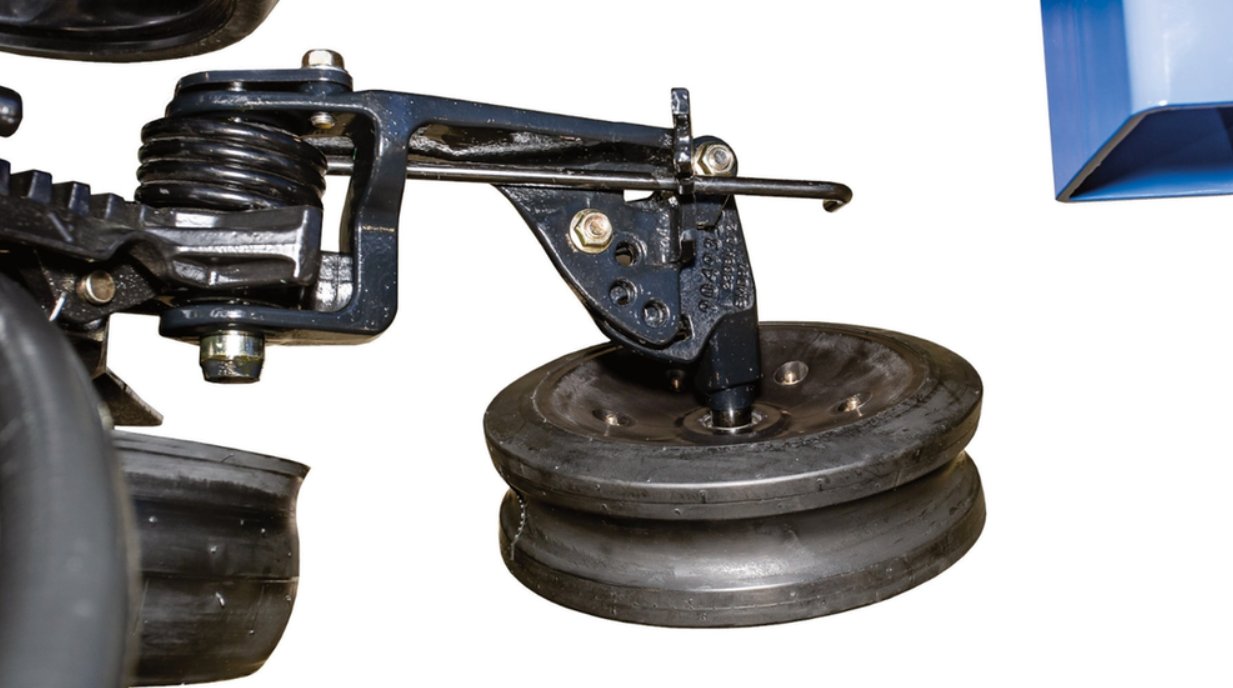

PRECISE DEPTH CONTROLNew larger-diameter, 18-inch gauge wheel helps clean off the coulter discs, reducing soil clumps. A simple, effective T-handle allows you to adjust depth in precise, quarter-inch increments from 1/2 inch to 2 inches in depth. The patented parallel link opener provides industry-leading ground following and accurate seed placement at high speeds and over rough terrain to ensure best-in-class seed emergence. |

CONSISTENT DOWN PRESSUREA heavier variable-pitch spring applies even down pressure so you can tailor the P2082 to match soil type and moisture conditions. |

EARLY EMERGENCE WITH OPTIMAL SEED-TO-SOIL CONTACT

|

PRODUCTIVE PERFORMANCE IN THE FIELDThe P2185 Disc Drill is available in 30 and 40 feet, with 7.5, 10 or 15 inch row spacing. The new frame design offers exceptional weight distribution that is ideal for many different crops and soil types. In addition, the narrow V-shape envelope adds additional stability for safe and convenient transport to and from the field. |

OPTI-ROW™ |

PARALLEL LINK DESIGN

|

DEPTH CONTROL

|

ACCURATE SEED PLACEMENT

|

ALL-NEW CLOSING SYSTEM

|

SECTIONAL CONTROL

|

UNMATCHED DURABILITY COMBINED WITH REDUCED MAINTENANCE COSTS

|

FRAME ACCESSIBILITY

|

MOUNTED SEED TANK

|

BEST WING FLEX IN THE INDUSTRY

|

BEST-IN-CLASS FLOTATION

|

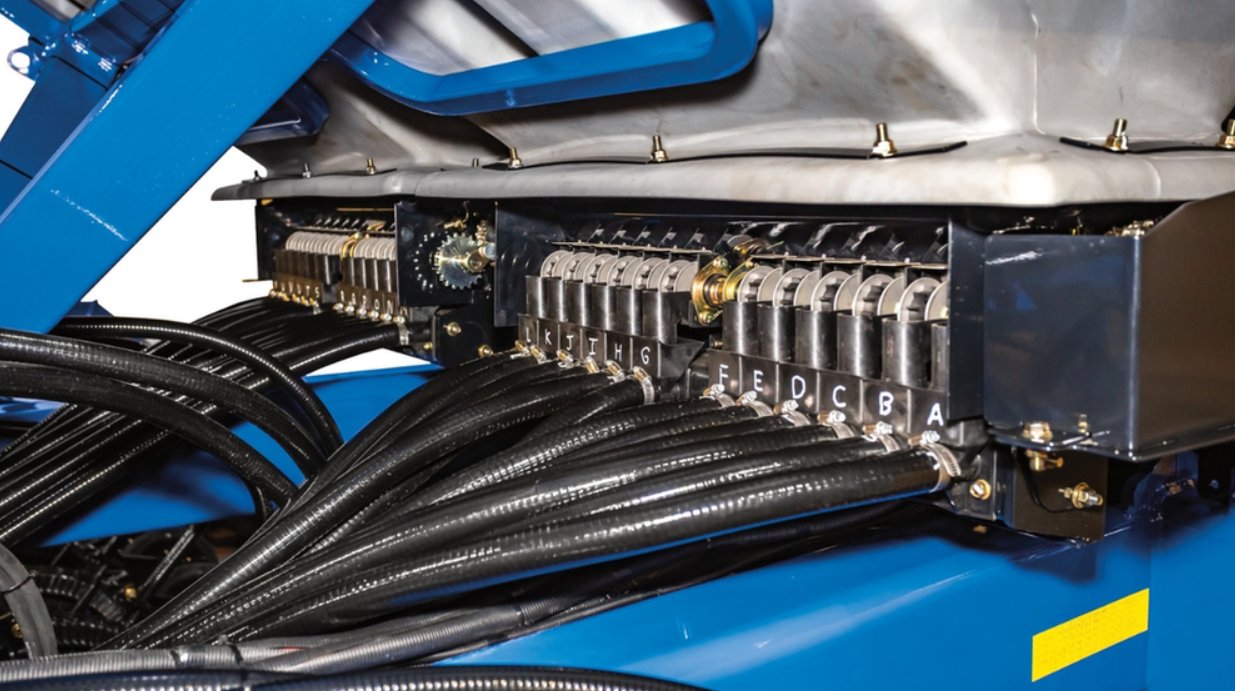

NEW SEED METER & DRIVE SYSTEM

|

|

Toolbar Width, ft (m) |

40 ft. (12.2) |

|

Available Spacing, in (cm) |

7.5 (19.1) & 10 (25.4) &15 (38.1) |

|

Transport height, ft (m) |

13' 10" (4.23) |

|

Transport width, ft (m) |

18.5 (5.63) |

|

Road-to-opener Clearance, in (cm) |

8' 6" (21.6) |

|

Weight 7.5 " spacing (empty), lbs (kg) |

28,360 (12,860) |

|

Weight 10 " spacing (empty), lbs (kg) |

25,660 (11,640) |

|

Weight 15" spacing (empty) |

22,380 (10,150) |

|

Length w/ rear hitch (pin to pin), in (m) |

_ |

|

Split rank capability, in (cm) |

15 (38.1) 20 (50.8) |

|

Number of row units 7.5" spacing |

64 |

|

Number of row units 10" spacing |

48 |

|

Number of row units 15" spacing |

32 |

|

Minimum tractor PTO hp required 7.5" spacing* |

260 |

|

Minimum tractor PTO hp required 10" spacing* |

195 |

|

Minimum tractor PTO hp required 15" spacing* |

131 |

|

Minimum tractor PTO hp required 7.5" spacing with air cart* |

325 to 360 |

|

Minimum tractor PTO hp required 10" spacing with air cart* |

_ |

|

Fold Type |

Single |

|

Wing Sections |

3 |

|

Tires total |

16 |

|

Center section walking beam castor tires |

380 / 55 R 16.5 D ply |

|

Rear mainframe dual walking beam tire size |

380 / 55 R 16.5 E ply |

|

High Flotation Rear Mainframe dual walking beam tire size |

500 / 40 R 16.5 E ply |

|

Inner and outer wings walking beam castor tire size |

340 / 60 R 15 D ply |

|

Operating Speed mph (kph) |

5-8 (8-12.7) |

|

Hitch Type |

Floating |

|

Ground following design |

Parallel link |

|

Row unit travel from level surface, in (cm) |

8.5 (21.6) up, 11.5 (29.2) down |

|

Wing flex |

15 degrees up, 10 degrees down |

|

Discs, in (cm) |

18 (45.7) at 7 degrees |

|

Gauge wheel options |

3" x 16" or 4.5" x 16" solid or spoked |

|

Depth settings, in (cm) |

14 position T-handle adjust from 0 to 3.5 (8.9) |

|

Down pressure adjustment |

Variable spring |

|

Closing wheel variable packing pressure, lbs (kg) |

60, 70 or 85 (27.2, 31.8 or 38.6) |

|

Standard in-cab down pressure control, lbs (kg) |

200 to 1400 (91 to 635) |

|

Hydraulic requirements, gpm (lpm) |

30 (114) – 3 remotes |

|

Hydraulic system |

In cab down pressure adjust standard |

|

Tow between/behind air cart capacity, bushels (l) |

_ |

|

Mounted Seed tank capacity, bushels (l) |

140 (4933) |

|

Mounted tank |

_ |

|

Display system |

Requires an ISO11783 compliant display such as Intelliview IV™ |

|

Sectional control |

4-section metering with overlap control |

|

Blockage Monitoring |

Outback blockage |

|

High floatation tire option |

Optional |

|

Hydraulic work switch |

Optional |

|

Weight bracket |

Optional |

|

Meter roll selection (extra fine, fine, coarse) |

Optional |

|

Auxiliary rear hitch |

– |

|

4-section metering with overlap control |

Optional |

|

Cross tillage hydraulic package |

– |

|

GPS speed sensor |

Optional |

|

Split-rank header insert, 7.5” (19.1 cm) |

– |

|

Primary run blockage |

– |

|

Secondary run (all run) blockage hydraulic work switch |

– |

|

1/2 width sectional control on air cart |

– |

|

Extended wear air package |

– |

|

Packer or gauge wheel deduct |

Optional |

|

Extended wear gauge wheel |

Optional |

|

Tank mounted weight scales |

Optional |

|

In-tank and rear-view cameras |

Optional |

|

Tank fill lighting package |

Optional |

|

Intelliview™ IV Display |

Optional |