|

|

|

Your cutting edge

|

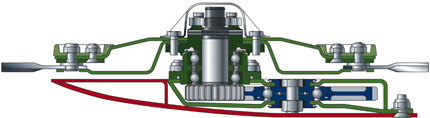

EasyCut – the better cut! The wedge-shaped cutterbar adjusts through a large setting range to cut short stubble in meadows and pastures and longer stubble in longstemmed field crops. EasyCut cuts blockage-free and clean. Benefitting from massive double spur gear bearings that are spaced at large gaps, the cutterbars are heavy-duty and hardwearing. |

Smooth and heavy-duty driveline: Massive and heavy-duty spur gears with up to 59 teeth take the pto power and transfer it to the discs without losses, ensuring each disc is driven full power. Each of the auxiliary gears uses smaller spur gears to drive one disc at a time, a design that minimizes the load on each gear and results in quiet running and longevity. |

|

High-comfort and high-efficiency mowers

|

|

AM – the working formula

|

|

Perfect in all conditions

|

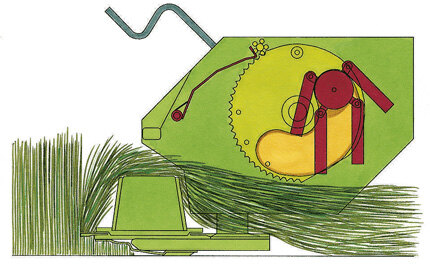

Constant-velocity and high-power driveline: Drive power flows through a frictional driveline of pto shafts and gears, a system that warrants an efficient transfer of power from the tractor down to the cutterbar discs – even in difficult conditions. Constant-velocity and high-power driveline: Drive power flows through a frictional driveline of pto shafts and gears, a system that warrants an efficient transfer of power from the tractor down to the cutterbar discs – even in difficult conditions. |

Absolutely safe: The KRONE break-back system relies on an adjustable coil spring, which responds instantly and dependably and allows the mower to swing back and up when impacting a foreign object. Absolutely safe: The KRONE break-back system relies on an adjustable coil spring, which responds instantly and dependably and allows the mower to swing back and up when impacting a foreign object. |

|

Technology that delivers

|

|

The dependable system Peace of mind comes from using innovative and top-quality machinery that impresses by an exemplary output – machinery like the KRONE range of AM disc mowers with working widths from 2.0 to 3.2 m (6'7"-10'6"), which has proven well around the world, feature superior stability and deliver excellent results. |

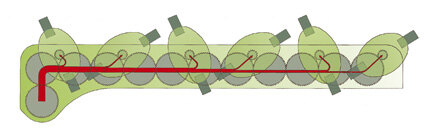

Linear crop flow: All KRONE disc mowers without conditioner feature a cantilevered guard that makes for an unobstructed flow of the material through the machine, delivering uniform swaths that speak for themselves. Linear crop flow: All KRONE disc mowers without conditioner feature a cantilevered guard that makes for an unobstructed flow of the material through the machine, delivering uniform swaths that speak for themselves. |

Operator comfort on the headland: On the headland, the mower is raised hydraulically to enable convenient turns and avoid running on cut material. The link arms are not raised. A stop limits the lift range. Operator comfort on the headland: On the headland, the mower is raised hydraulically to enable convenient turns and avoid running on cut material. The link arms are not raised. A stop limits the lift range. |

|

Top-quality forage across the full working width

|

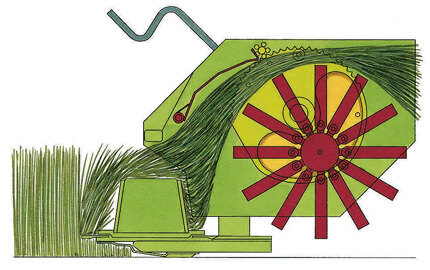

Success delivered – V-shaped steel tines: Efficiency is one parameter in hay and forage harvesting, quality is another. The AM 243 CV model features a mechanical conditioner with V-shaped steel tines and mechanical gearbox, which provide optimum crop conditioning, fast and uniform wilting and top-quality forage. Freely pivoting steel tines treat every single stem and achieve an outstanding quality of crop. Success delivered – V-shaped steel tines: Efficiency is one parameter in hay and forage harvesting, quality is another. The AM 243 CV model features a mechanical conditioner with V-shaped steel tines and mechanical gearbox, which provide optimum crop conditioning, fast and uniform wilting and top-quality forage. Freely pivoting steel tines treat every single stem and achieve an outstanding quality of crop. |

It’s intensive: Pivoting V-shaped steel tines combine with an infinitely adjustable baffle plate to provide intensive conditioning, reduce machine wear and optimize adaptation to crop conditions. It’s intensive: Pivoting V-shaped steel tines combine with an infinitely adjustable baffle plate to provide intensive conditioning, reduce machine wear and optimize adaptation to crop conditions. |

It’s stepless: This crank varies the clearance between tines and baffle plate to adjust the conditioning effect. The narrower the clearance, the more intensive the conditioning. It’s stepless: This crank varies the clearance between tines and baffle plate to adjust the conditioning effect. The narrower the clearance, the more intensive the conditioning. |

It’s perfect: The operator sets the clearance between rotor and cutterbar as he pivots the conditioner, adjusting the system to current yields and degree of lignification and achieving a perfect cut and exemplary conditioning. It’s perfect: The operator sets the clearance between rotor and cutterbar as he pivots the conditioner, adjusting the system to current yields and degree of lignification and achieving a perfect cut and exemplary conditioning. |

It’s simple: When using the machine for cutting daily rations or legumes, the operator swings the rotor conveniently to the rear and out of work to use the machine as a plain mower. It’s simple: When using the machine for cutting daily rations or legumes, the operator swings the rotor conveniently to the rear and out of work to use the machine as a plain mower. |

|

Put in less – fi nish earlier - Increased wilt and less exposure to weathe r - Fewer passes and reduced conditioning costs - Optimum treatment for optimum quality |

|

Spread as wide as possible and as narrow as necessary: Scientific research has shown that spreading has a significant effect on fermentation and quality of the forage. Accordingly, the hood not only spreads the material across a large area but also produces light and fluffy swaths, saving you at least one tedding pass in many conditions for improved forage quality, milk performance and reduced reliance on concentrates. |

|

Full-width conditioning: Specified with V-shaped steel tines, baffle plate, aluminium hood and optional deflector plates, the conditioner spans across the machine’s full work width. The design provides for a consistent flow of crop and uniform spreading. |