Jacto

Jacto - Uniport 2530

|

Strength to face any challenge. |

|

Operations center: Simplicity and handling for carrying out operations; everything located on one side of the equipment;

Incorporation: Allows working with liquids and solids efficiently and quickly in the operation;

Mechanical spray agitation: Correct spray mixture homogenization, agitation is independent of the flow in the spray circuit, which allows better quality in the application;

Electronic spraying control: Equipped with a piston pump and electronic control system, it works with great precision and short response time; together with an 8-way controller, they allow operations with less overlap and greater efficiency in the use of pesticides;

|

|

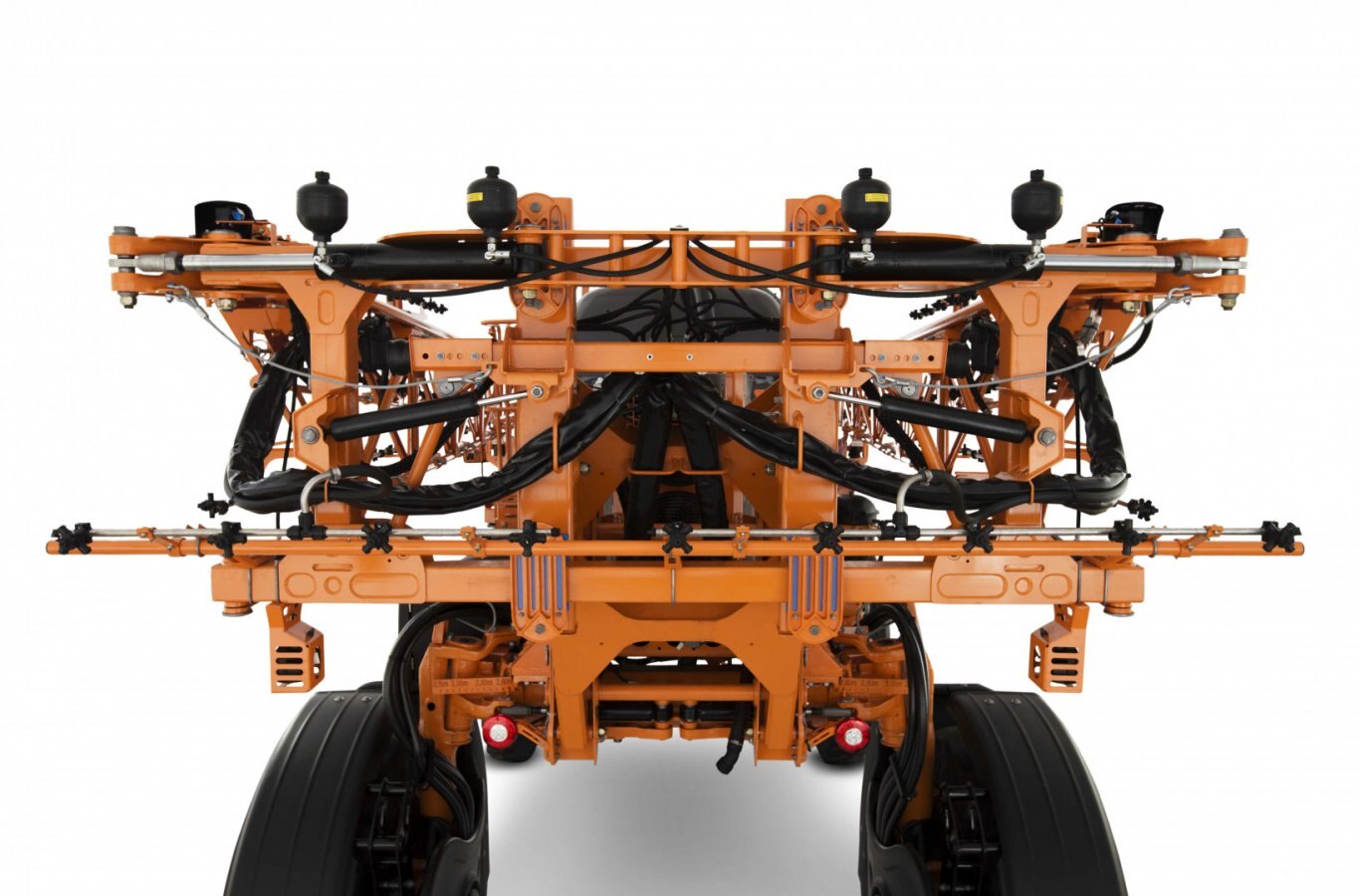

4x4 hydrostatic transmission system with intelligent traction control, integrated with the 198 hp diesel engine and the ideal weight distribution between the axles allows spraying on terrain with a slope of up to 30%; the system automatically identifies the need for traction control in the vehicle without the need for the operator to act; more comfort and precision in the spraying operation; exclusive braking system with hydraulic ABS control integrated into the transmission system; more safety in the operation of the equipment with comfort and precision in the spraying operation, reducing fuel consumption. |

|

With its transmission system and reduced weight, the Uniport 2530 can operate at speeds of up to 25 km/h in the spraying operation and 40 km/h in displacement; equipped with booms of 30 or 36 meters. With a boom of 36 meters, the Uniport 2530 when compared with equipment that has booms of 30 meters, provides an increase in operational efficiency by up to 15% and reducing crop dents by up to 8%, daily performance can reach up to 630 hectares a day. The boom stability system with trapezoidal hydraulic suspension adapts to different types of terrain; it has the exclusive feature of the operations copier that allows to optimize and standardize the spraying operations in a simple and agile way. |

|

With 18993 lb (empty machine) when equipped with a 98 ft boom, it allows to operate with low pressure on the tires, reducing soil compaction and increasing crop productivity, all with low fuel consumption; less weight to pull the equipment. |

| Lenght | 25.9 ft (98 ft boom) | 26 ft (118 ft boom) | ||

| Maximum Width | 10.5 ft | |||

| Height | 12.95 ft (13.6x38) | 12.81 ft (IF340/85 R38) | 13.1 ft (IF320/90 R42) | 13.1 ft (VF320/90 R42) |

| Distance between Axis | 12.5 ft | |||

| Ground Clearance | 5.25 ft (13.6 x 38) | 5.12 ft (IF340/85 R38) | 5.38 ft (IF320/90 R42) | 5.38 ft (VF320/90 R42) |

| Track Width Adjustment | 8.5 up to 10.3 ft | |||

| Weight (empty machine) | 18993 lb (98 ft boom) | 20900 lb (118 ft boom) | ||

| Fuel tank | Capacity 73 gallons | ||||||||||

| Transmission | 4x4 hydrostatics with independent electronic traction control | ||||||||||

| Suspension | Independent, with pneumatic springs and hydraulic shock absorbers. | ||||||||||

| Tires | IF320/90 R42 (optional) | 13,6 x 38" (series) | IF340/85 R38 (optional) | VF320/90 R42 (optional) | |||||||

| Engine | Model Cummins QSB 4.5 |

Emissions MAR-I |

Maximum power 198 hp @ 2.200 rpm |

Fuel Diesel or Biodiesel B20 | |||||||

|

Lightbar |

Omni 700 (series) | GFX-750 (Optional) | |

| Hydraulic autopilot | Omni 700 (series) | GFX-750 (Optional) | |

| GPS signal corrections available | TerraStar C | TerraStar C PRO and RTK (Omni 700) | RTX or RTK (GXF 750) |

| Automatic section controller | 8 sections | ||

| Operations Repeater | Agis (only for Omni 700) | ||

| Temperature and humidity sensor | (series) | ||

| Variable application rate | (optional) | ||

| Ekos | Solutions for agricultural operation management (series) | ||

| Brochure Uniport 2530 | Download |