Chromium molybdenum frame Chromium molybdenum frame

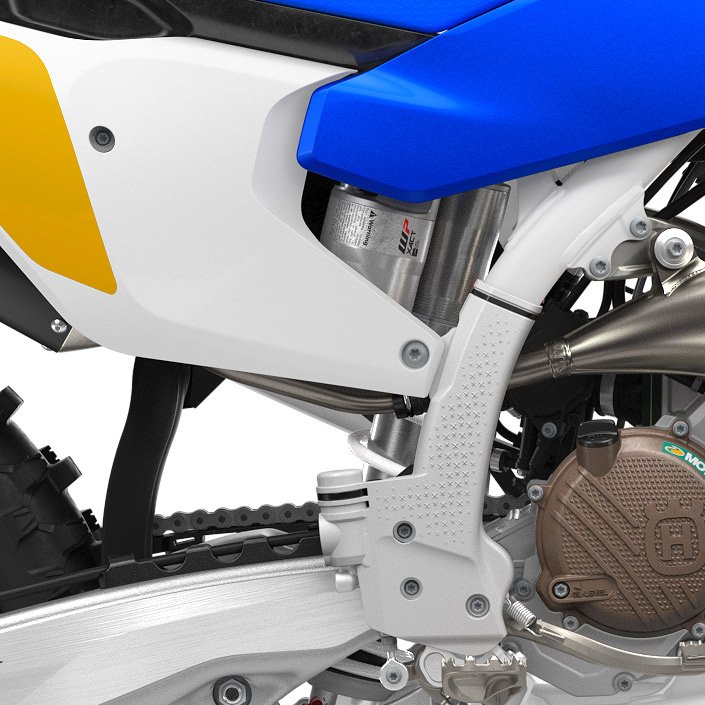

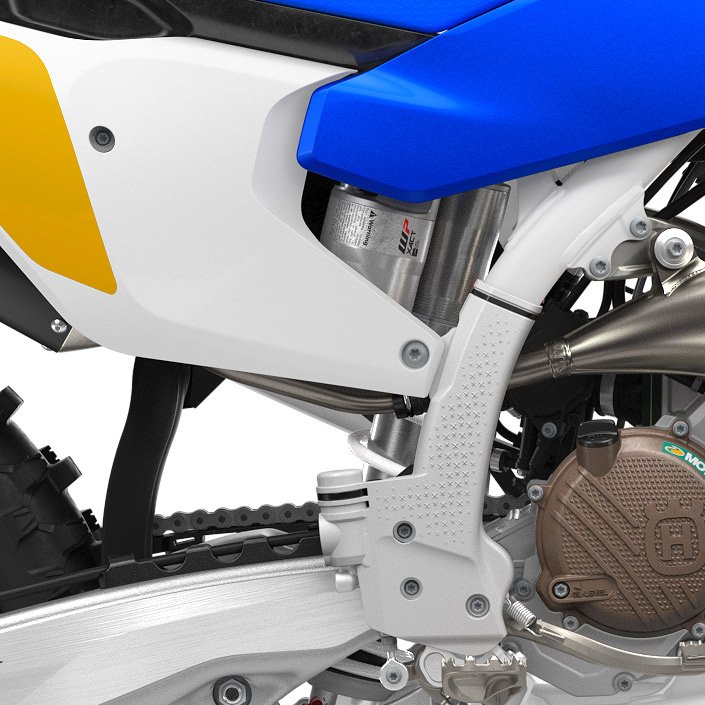

The proven chromium molybdenum steel frame is refined for 2023. A new shock mounting, which is no longer connected to the main tube, significantly improves the anti-squat behaviour of the chassis. With optimised wall thickness in high stress areas improving reliability, the frame continues to offer advanced geometries and flex characteristics aimed at providing unparalleled rider feedback, energy absorption, and exceptional straight-line stability. The frame is finished off in a premium white powder coating with redesigned standard frame protectors offering superior protection, durability, and grip in any condition. Additionally, the inclusion of forged brackets on the lower frame rails allows for easy installation of the skid plate, which is available as a technical accessory. |

Polyamide-reinforced aluminium subframe Polyamide-reinforced aluminium subframe

Made from 60% polyamide and 40% aluminium, the new two-piece subframe for 2023 ensures exceptional strength and durability at an overall weight of just 3.9 lb (1.8 kg). The lower subframe spars and frame mounts are manufactured from cast aluminium for significantly improved reliability. The upper section of the subframe is made from injection-moulded polyamide to enable specific flex characteristics and ensure a lightweight construction. |

Triple clamps Triple clamps

Working in unison with the frame design and suspension set-up, the CNC-machined triple clamps ensure precisely calculated geometry for assured stability. Handlebar flex can be customised with the handlebar clamp, which offers two mounting options - rubber-damped for less vibration, or fixed for enhanced front-end feedback. The upper triple clamp is stiffer to ensure a smoother fork action and plays a vital role in the perfect alignment of the front wheel for superior handling. |

WP XACT front suspension WP XACT front suspension

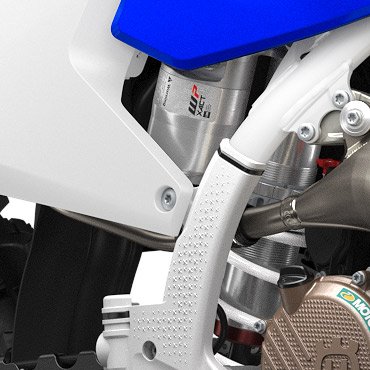

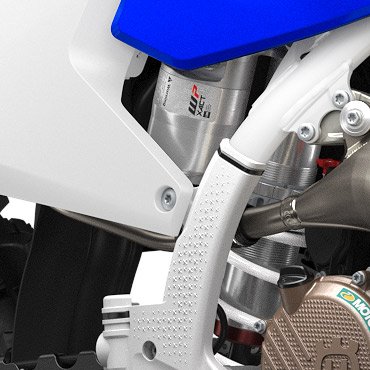

The 48 mm WP XACT forks feature a closed cartridge system and a capsulated, adjustable air spring. Together with a pressurised oil chamber, the forks deliver a smooth action and consistent damping. Oil and air bypasses reduce pressure peaks and in combination with the mid-valve damping system, the forks provide precise feedback to the rider. To ensure maximum forward momentum after heavy landings, a hydrostop applies a progressive damping force in the last 40 mm of travel. The settings are easily adjusted via the single air pressure pre-load valve, as well as through easy access click adjusters for compression and rebound. Additionally, the pump needed to adjust the air spring pressure in the forks is provided with each Heritage machine. |

WP XACT shock absorber WP XACT shock absorber

The all-new WP XACT rear shock is 100 g lighter and 15 mm shorter than its predecessor yet the travel remains unchanged. Inside the shock is a Computational Fluid Dynamics (CFD) optimised main piston for improved initial comfort which provides strong hold-up in all conditions. Different sized holes in the shims allow them to open more easily which reduces the overall stress of the oil flow. Complete with low friction SKF seals and a revised linkage system, consistent damping, comfort, and traction are guaranteed with rebound and both high and low speed compression now adjustable by hand. |

Swingarm Swingarm

The swingarm is manufactured using a die-cast production process for optimal rigidity. To optimise and match the flex characteristics of the chassis, a 22 mm rear axle is utilised. Additionally, the chain slider is exceptionally durable while the chain guide is manufactured with a rounded profile to ensure it is less prone to catching on external objects. |

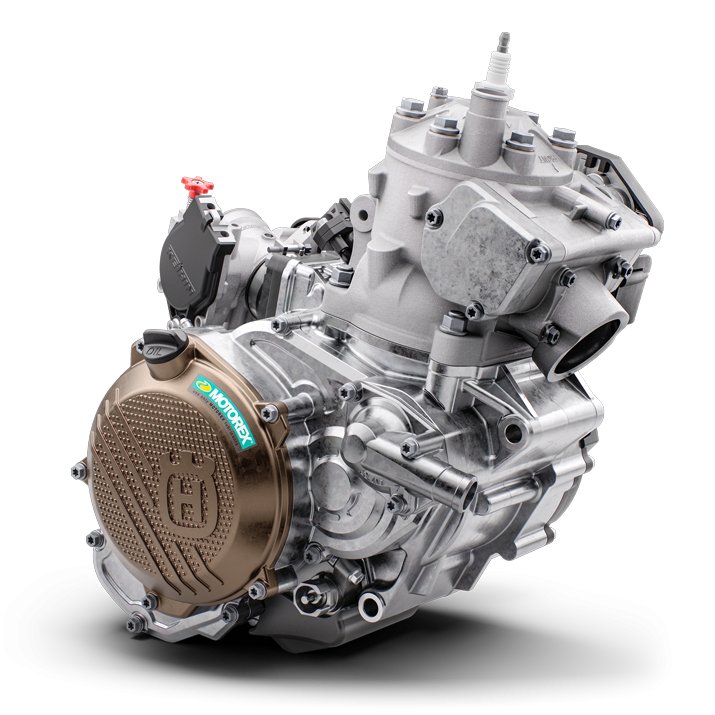

Engine

Engine Cylinder

Cylinder Crankshaft

Crankshaft Crankcases

Crankcases Counter balancer shaft

Counter balancer shaft Gearbox

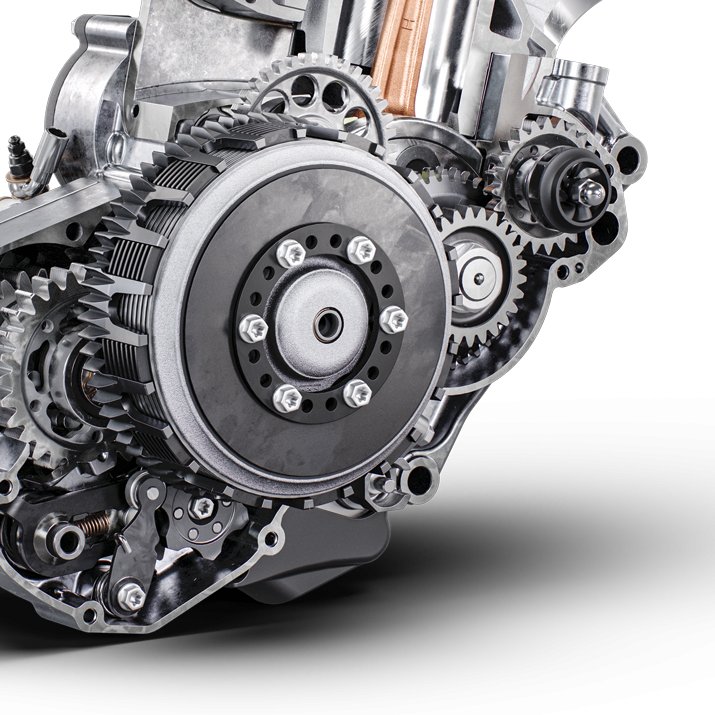

Gearbox DDS clutch

DDS clutch Chromium molybdenum frame

Chromium molybdenum frame Polyamide-reinforced aluminium subframe

Polyamide-reinforced aluminium subframe Triple clamps

Triple clamps WP XACT front suspension

WP XACT front suspension WP XACT shock absorber

WP XACT shock absorber Swingarm

Swingarm Functional bodywork

Functional bodywork Airbox

Airbox Hydraulic clutch

Hydraulic clutch Hydraulic brakes

Hydraulic brakes ProTaper handlebar

ProTaper handlebar ODI grips

ODI grips Footrests

Footrests Wheels and tyres

Wheels and tyres Exhaust system

Exhaust system Cooling system

Cooling system Fuel tank

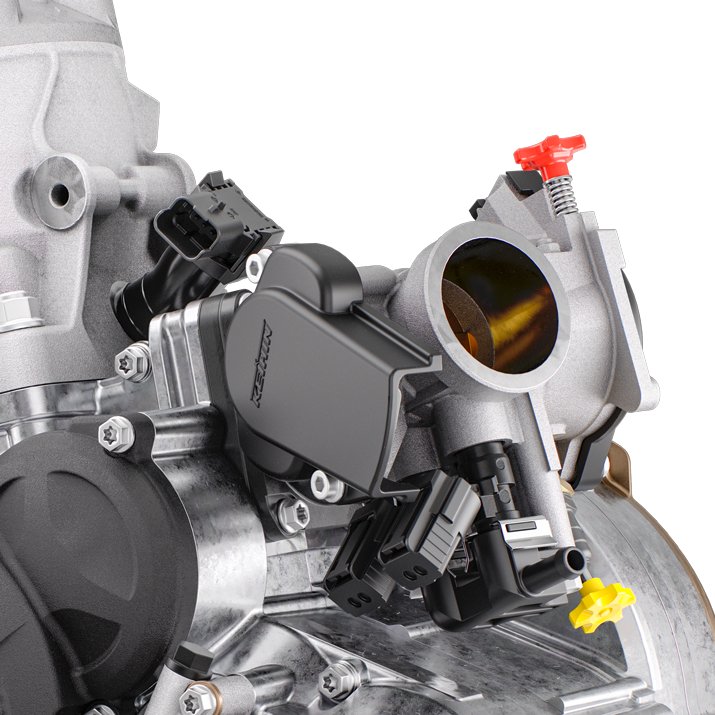

Fuel tank EFI

EFI E-Start

E-Start Map Select Switch

Map Select Switch EMS

EMS Hour meter

Hour meter Start/stop switch

Start/stop switch