Honey Bee

Honey Bee - Rice Belt Header

Rugged, Ground-hugging Header for RiceThe Honey Bee Rice Belt Header speeds harvest with features that allow it to hug the ground for faster, easier harvests eliminating the twisting and tangling problems associated with conventional auger headers. Using drapers and a unique feeding auger, the Honey Bee Rice Belt Header uniformly feeds the crop heads first into the combine providing constant harvest speeds, superior threshing and better harvest efficiency, increasing combine capacity by as much as 20 percent. Plus, it is ruggedly designed to last longer with less down time. The Rice Belt Header not only ensures proper feeding of rice, but also can be used on any crop from wheat to lupins. When converting from straight-cut to a pick-up header, no combine adjustment is necessary. Few crops around the world are as difficult to harvest as rice. The stalks are tough, rice is particularly abrasive, and yields can run upwards of 295 bushels per acre. In addition, you’re often harvesting in extremely wet ground conditions. They all add up to tough combining with conventional equipment. Honey Bee lives to make harvests faster. Starting with an understanding of material flow into a combine, Honey Bee has engineered a better straight-cut header especially for rice. Built on a design that moves the crop smoothly to the feeder housing, the Rice Belt Header defines harvest efficiency with low maintenance features such as an oversized oil cooling reservoir and heavy duty 3/16″ tubular steel header mainframe. The Rice Belt Header is a rugged, ground-hugging header that is designed to last. Add in Honey Bee’s reputation for well-built, dependable equipment and you’ll have a lot more harvest time on your hands. |

| 21′ | 25′ | 30′ | 36′ | |

|---|---|---|---|---|

| Width | 21′ (6.4 m) | 25′ (7.6 m) | 30′ (9.1 m) | 36′ (10.9 m) |

|

Weight* (no reels or options included) |

5,269 lbs (2,390 kg) |

5,911 lbs (2,681 kg) |

6,786 lbs (3,078 kg) |

7,200 lbs (3,266 kg) |

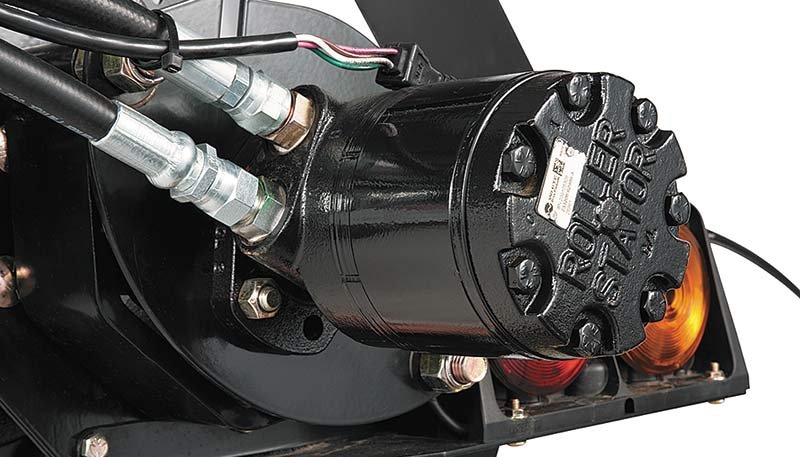

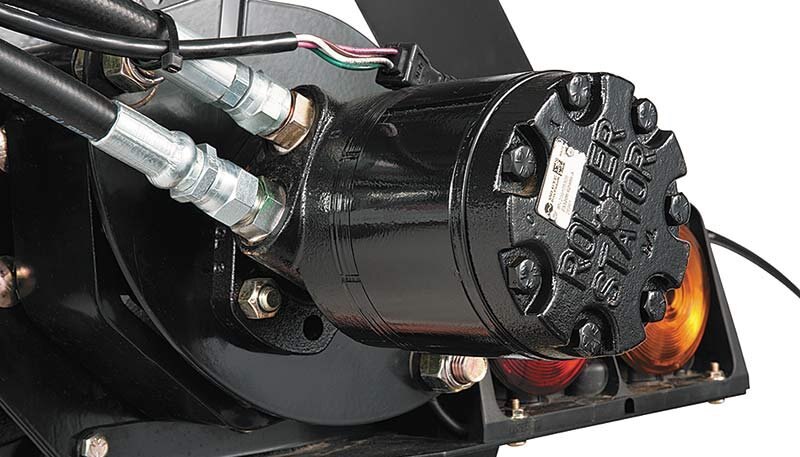

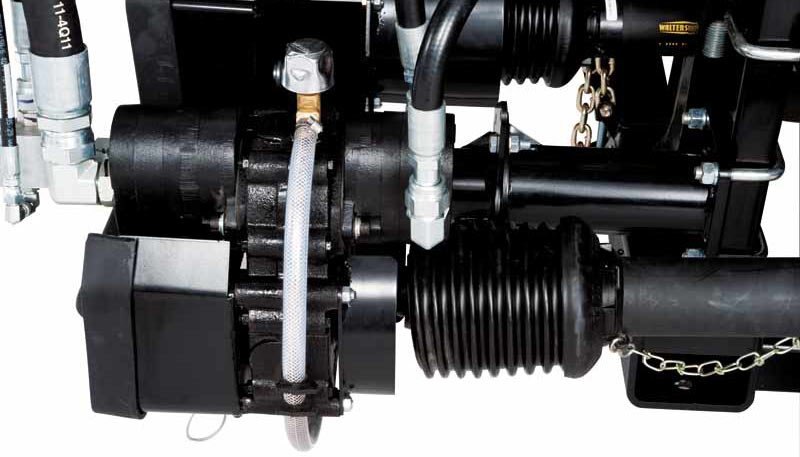

| Hydraulic System | Self contained hydraulic system on the header. Single gear pump with step up gear box driven off of bottom feeder house. | |||

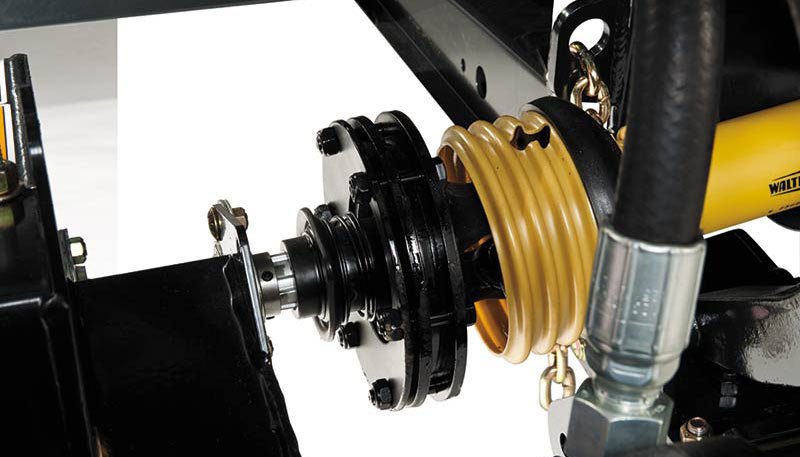

| Header Floatation | Leaf spring float system standard on all models. | |||

| Cutting System | SCH Easy Cut, spring steel guards, bolted sections, roller spacer bar. | |||

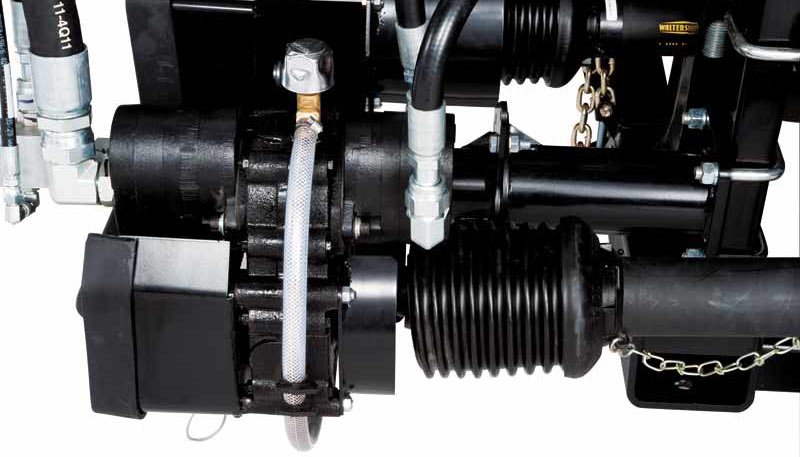

| Knife Drive | SCH 3 5/16″ (8.4cm) stroke, hydraulically driven, approximately 1,100 – 1,300 strokes per minute. | |||

| Standard single drive with option of double drive knife. | ||||

| Draper | 42″ (106.7 cm) wide rubberized polyester, fibreglass reinforced rubber slats. Hydraulically driven. | |||

| Centre Deck | Hydraulically driven, 68″ (172.7 cm) wide centre canvas. Speed adjustable on header. | |||

| Feed Auger | Mechanically driven, 18″ x 72″ (45.7 cm x 182.9 cm) retractable finger auger. | |||

| Reel(s) | 21′ | 25′ | 30′ | 36′ |

| Pickup Reel – Universal UII, (Series 2) 6 bat, 42″ (106.7 cm) diameter, plastic teeth only. | ||||

| Pickup Reel – HCC Polytine Level II series, 6 bat, 42″ (106.7cm) diameter. | ||||

| Reel Drive | Standard – using combine hydraulic system. Header driven reel optional. Reel speed adjustable in cab. | |||

| Gauge Wheels | Optional | |||

| Storage Transport | Optional | |||

| Formed Fit Poly Skid (UHMW) | Standard | |||

| Combine Adapters | Available for most models of self-propelled combines. | |||

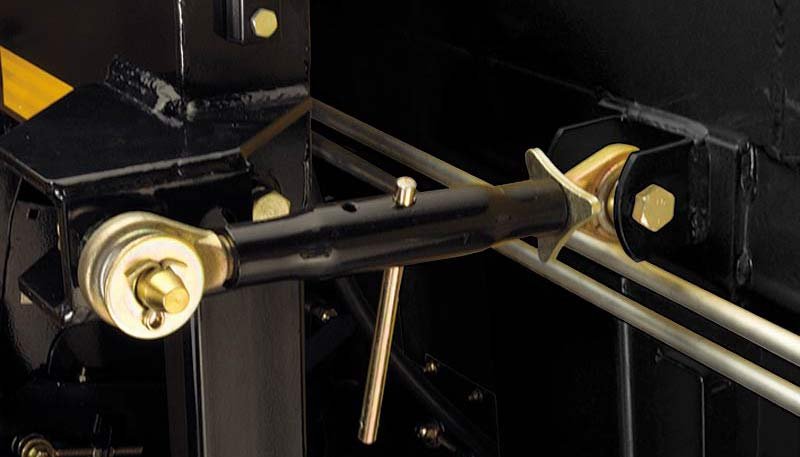

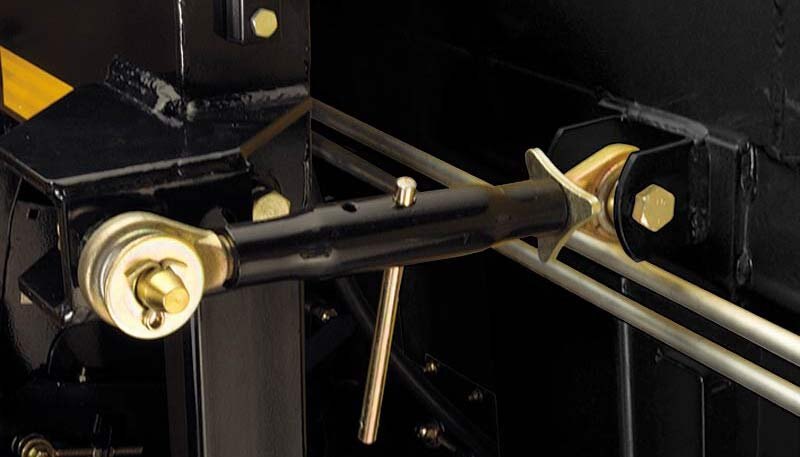

| Fore/Aft | Standard | |||

| Automatic Header Height Control | Optional | |||

|

|

|

|

|

|

|

|

|

|

A PTO driveline powers a hydraulic pump that is mounted to a step-up gear box that drives the feed auger. The step-up gear box is lubricated with oil supplied from the header hydraulics, which is double filtered to keep the system clean. |

|

|

|