Hardi

ID # 13609118

Hardi Saritor

Call for Price

Overview

Specifications

Videos

Documents

|

In front of the field

The SARITOR with infinitely variable four-wheel drive hydrostatic transmission delivers the traction to stay in front of the sprayer range. SARITOR is HARDI-built from the ground up and sets new standards in broad acre spraying. It offers a 1,300 gal. tank capacity with 88 - 132 ft. TERRA FORCE BOOM or an ALU FORCE 120 - 132 ft. option. Crop clearance is 54 in., and the track width can be hydraulically adjusted from 120 - 157.5 in. providing a large stable platform for boom stability. |

|

Features |

The large cab is uncluttered and offers top level comfort. It is quiet and provides excellent operator visibility. Climate control air conditioning with 10 air outlets provides set-and-forget operation and gives maximum operator comfort levels. Dust and carbon filter ensures good air quality circulation. |

Everything you need is at your finger tips. All managed through the HC 9600 display and SprayCenter control console. Spraying has never been easier. The joystick combines the hydrostatic drive and vital spraying control functions. Forward, reverse and braking are operated by pushing forward or pulling back on the joystick. Spray ON/OFF, section control, boom height and wing tilt functions are also managed from the joystick. All the secondary control functions are managed from the SprayCenter. |

The chassis is made from high tensile steel (DOMEX® Swedish steel) to provide low weight, strength and flexibility. The U shape chassis rails with bolted cross members are a technology derived from the heavy vehicles industry and offer incredible flexibility. All the main components like engine, main tank, RinseTank, pump etc. have been placed to optimize the weight distribution between front and rear axles. |

Quick and easy hydraulic track width adjustment for on road transport or in field operation. On-the-go adjustment Individual 9.8 - 12 ft. adjustable axles suit a variety of row crop applications and provides enhancing boom stability. Powerful A hydraulic cylinder is protected inside each axle and provides smooth and immediate adjustment. |

The 4WD hydrostatic transmissions are optimised for electro-hydraulic control and are coupled to intelligent electronics using the Sauer graphics terminal DP 250. The intelligent electronics are integrated into the Cummins “CAN” communication platform to ensure the engine power is optimised to the wheel motor torque which delivers smooth performance. The wheel motor output is matched to the engine torque, optimising fuel efficiency and the transmission operating pressure. |

The SARITOR is ideal in broadacre and row crop applications. With a turning circle of 67 ft. curb to curb with the largest tires the SARITOR is designed to have the best turning radius possible to prevent crop damage in the headlands. The turning radius of 21.4 ft. is measured to the center of the inner wheel at 14.1 ft. track width. The wheel base of the SARITOR is 13.8 ft. ensuring a stable platform when spraying in rough terrain. |

|

Fluid System |

The HARDI TurboFiller is developed to handle large quantities of powders and liquids. Its high capacity is achieved through a combination of high vacuum and liquid rotation produced by a TurboDeflector inside the hopper. High mixing capacity Liquid at high pressure is being used to create a powerful rotation of the liquid inside the hopper. This movement gives the effect that every powder or liquid chemicals are mixed before they are sucked into the sprayer. The highest capacity is achieved when the TurboFiller is more than half-filled with water. Optimum filling height A spring-loaded bracket with transport lock makes it easy to change from field to filling position. The filling position is approx 3 ft. from the ground. |

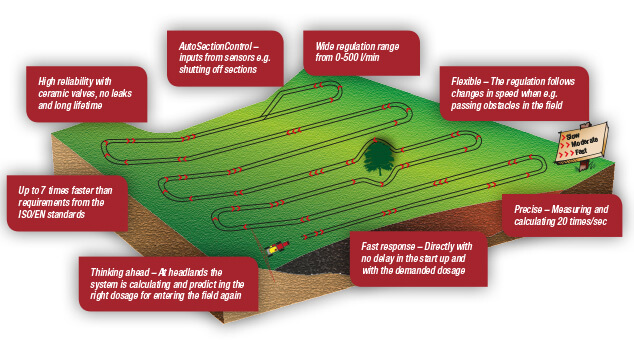

The SARITOR DynamicFluid4 fluid system is driven by a high performance HARDI 650 Wet seal run-dry centrifugal pump, which can achieves 15 to 30 gpm. rate change in 1.5 seconds. The SARITOR fluid system delivers the target rate without lag whether sections are switched on or off, changing speed or turning in or out of headlands. Advanced fluid dynamics and rate control processes are employed to deliver fast response and accurate target rate application.Pressure, flow, pump speed, forward speed, boom sections and application rate is monitored and processed using advanced computations. The DynamicFluid4 processor analysis the spraying data 20 times a seconds and provides preemptive rate control capability, altering the pump speed with pin-point precision.The proportional hydraulics used to control the pump speed are highly accurate, smooth but incredibly fast. |

The WorkZone console provides switching for electric motor drive valves that control main or RinseTank, Venturi, pump ON/OFF, tank rinse nozzles, boom nozzle, engine rpm and agitation. A LED identifies which valve is in operation. |

|

Chassis, Engine & transmission |

The new Tier 3 compliant Cummins QSB 6.7 engine takes you to a whole new level of power, versatility and emissions control. Achieving Tier 3/Stage IIIA compliance with in-cylinder technology that maintains a compact, simple and cost-effective engine. The QSB 6.7 offers major enhancements that makes the SARITOR work harder, smarter, quieter and longer…every time. The engine is power rated to 275 hp (205 kW) with charge air cooling and turbo charging for strong performance. |

4WD hydrostatic transmission Designed for intelligent self-propelled sprayer drive management, the Sauer-Danfoss H1 Transmission delivers a new level of performance with reduced fuel consumption and high operator comfort. Sauer-Danfoss H1 transmission pumps minimise control and charge pump losses, which maximises available engine power. In addition the Sauer-Danfoss H1 bent axis wheel motors offer significant overall efficiency and an extremely low pressure drop within the fluid reservoirs of the motor |

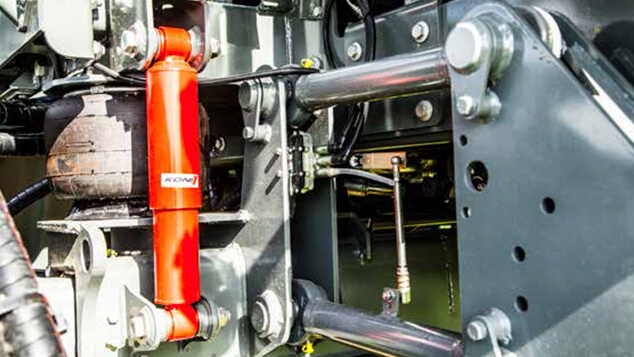

Auto level air ride suspension combined with the flexible high strength chassis delivers an enviable ride for the operator. Front axle suspension Independent ride level air bag suspension with two heavy-duty shock absorbers provides exceptional ride and performance. Rear axle suspension The heavy-duty trailing link-arm suspended rear axle is equipped with independent air bag suspension for smooth ride and performance. |

A high resolution multi-functional display terminal for both control of operation of engine, transmission and operator selected control choices. System can be set for metric or imperial display. It displays a series of engine, transmission and sprayer status in graphis or digital form. Furthermore is a ‘fault display terminal’ which stores and displays various error codes. |

// SARITOR delivers exceptional ride comfort and boom performance with the help of four large air bag suspension elements assisted by hydraulic shock absorbers. // The under chassis crop clearance is 54 in. and the track width is hydraulically adjusted from 120 - 157.5 in. At 157.5 in. wide track provides an exceptionally stable platform enhancing boom ride and performance. // Each wheel axle can be hydraulically adjusted independent on the others providing for the opportunity to run the front and rear at different track widths if required. |

|

Boom |

// Built strong utilising heavy-duty threedimensional truss construction for high performance and is available in sizes 88 to 132 ft. // The TERRA FORCE truss boom design is able to withstand incredible yaw forces created during cornering, accelerating, braking and auto steering. These forces are absorbed through a hydraulically dampened parallelogram suspension system. // With on-the-go stability control the dynamic boom center can be set from the cab to suit the operating condition. // When the boom is open, the wing locks provide a positive locking mechanism ensuring the wing performs as one. // The TERRA FORCE boom is designed to reduce turbulence over and around the nozzle. |

AutoTerrain

AutoTerrain

// TERRA FORCE with optional AutoTerrain sets new standards in wide boom performance. AutoTerrain maintains a lower boom height and provides better drift control. // AutoTerrain maintains the set boom height following the ground like a magnet regardless of the terrain it travels across. // AutoTerrain is a pre-emptive stability and auto height control system that deals with the cause of boom movement. // AutoTerrain seamlessly monitors roll through the center and the height of the boom off the ground 10 times every second. When a change is detected, // AutoTerrain simultaneously corrects the boom position relative to the ground contour by angling it through the center pendulum. |

|

Controls |

The ElectricFastControl (EFC) is a modular system with a positive drive motor valve for each section and a single pressure dump valve, when all sections are switched to OFF. The section valves incorporate a pressure dump. When the section is switched to OFF, the pressure in the line to the nozzles is relieved. This results in instant shut-off at the nozzles. The EFC does not need any form of adjustment, e.g. pressure equalisation. |

All the main spray functions are at your fingertips. The multi-function joystick in conjunction with the 12.1” touchscreen provides the HC 9600 user with the highest level of performance available. The HC 9600 controller provides growers with a powerful and full featured precision farming tool. Features include guidance, data logging, application reports, GPS controlled spraying, automated steering and more! |

Model

Saritor

Category Name

Agriculture

Year

2020

Sale Type

New

Manufacturer

Hardi

Tank

1,300 gal. (5000 ltrs)

Engine

Cummins QSB 6.7 L 275 hp

Boom Type

TERRA FORCE or ALU FORCE

Controller

HC 9600

Suspension

Pneumatic suspension + shock aborbers

Wheel Base

168 in. (4.26 m)

Pumps Type

Ace 650 run-dry centrifugal

Total Length

374 in. (9.5 m)

Transmission

4-WD Danfoss Hydrostatic H1

Pump Capacity

180 gpm. (680 ltrs)

Track Adjustment

120 to 157.5 in. (3 to 4m) hydraulic

Fuel Tank Capacity

145 gal. (550 ltrs)

Weight (empty) W/ 120 Ft. TDZ

30,250 lbs. (13,721 kg)

Total Transport Height W / Wheels Set 380/90 R50

156.5 in. (3.96 m)

Model

Saritor

Category Name

Agriculture

Year

2020

Sale Type

New

Manufacturer

Hardi

Quantity

0

Tank

1,300 gal. (5000 ltrs)

Engine

Cummins QSB 6.7 L 275 hp

Boom Type

TERRA FORCE or ALU FORCE