Geringhoff

ID # 13528626

Geringhoff Rota Disc Elite XL

Call for Price

Overview

Specifications

Videos

|

Features |

Foundation

Success must be built upon a solid foundation. The Geringhoff Elite XL Series was created upon the form and function of an advanced aircraft. Durability and flow were forged alongside the concepts of lighter weight and superior longevity. The Elite Series offers an exceptionally smooth and quiet running system, despite it's fierce appetite during harvest. The Elite XL Series also features Geringhoff's exclusive Integrated Crop Flow system; 6 standard features and two optional features that when combined offer the world's finest harvesting experience. With all the Elite XL Series features in place, changing field conditions won't stop you from bringing in your crop on your terms. |

Technology

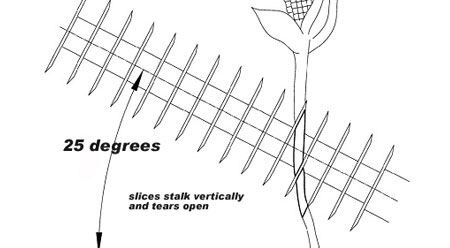

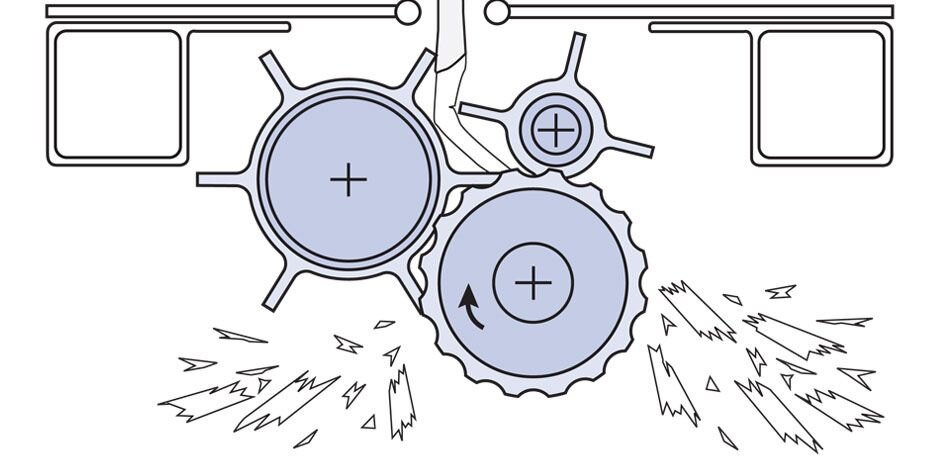

Stalks are aggressively fed into the Rota Disc and are continuously transported rearward while being pulled down through the stalk destruction system. Durable cutting discs create small pieces uniquely exposed by a 25 degree cut and a vertical slice to the remaining stalk. The effectiveness of this well engineered process is not reduced by an increase in ground speed. The Rota Disc system draws a mere 2.5-3.0 additional horsepower per row to complete the stalk destruction. This unique design will speed you through harvest and leave a distinctly processed field behind. The stalks will be vertically sliced, shredded and evenly distributed, ready for rapid decomposition. The Rota Disc is recognized as the industry’s most efficient stalk destruction corn header. Maximize your harvest potential with the outstanding quality and superior performance of the Rota Disc. Experience reduced fuel consumption, reduced downtime and fewer maintenance requirements. Geringhoff owners consistently rank their machines as a major contributor to increased yields as the entire machine is designed to minimize kernel loss and efficiently deliver more cobs to the combine feeder house. |

True Vertical Stalk Destruction |

|

Horsepower Requirements

|

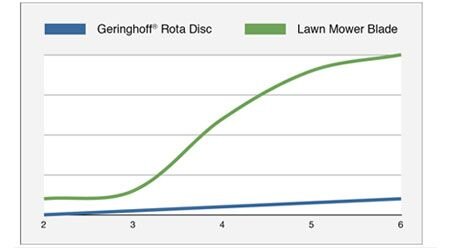

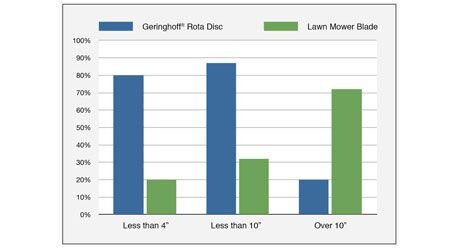

Residue Size

Residue Size

The Rota Disc system consistently processes the majority of stalk remnants to less than 4" in length. Compare this to the lawn mower style choppers that primarily process stalks to only 10" in length or more. |

Finely Chopped Residue Finely Chopped Residue

The interior of the stalk is exposed for faster decomposition and quicker decay. |

Exploded Stalk

Notice how the ground stalk looks exploded. This creates conditions for accelerated stalk decomposition and reduced wear on your combine and tractor tires. |

Clean Looking Field Clean Looking Field

Rota Disc stalks are primarily shredded into 4"-8" pieces |

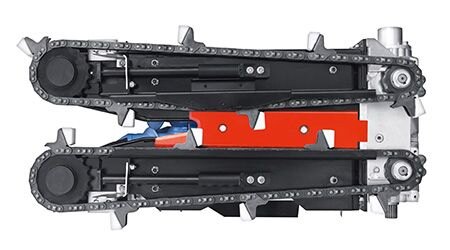

Row Unit - Top1. Poly Return Sprocket

2. Automatic Chain Tensioner

3. Beveled Drive Sprocket

4. Gathering Chains

5. Double Acting Automatic Hydraulic Deck Plates

|

Row Unit - Bottom6. Hardened spiral rolls

7. Stationary Knife and Stubble Cutter

8. Picking Rollers

9. Single Component Design

10. Vine Cutter

11. Roller Bushings

12. Trash Deflector

|

Row Units Continued

|

|

|

ICF System

Time is money, especially when it comes to running harvest equipment. Geringhoff's new Integrated Crop Flow System is designed to increase your harvesting speed while reducing shatter and cob losses. You'll reduce the hours spent behind the controls of your combine and maximize the profitability of your harvest in all field conditions. Six standard features work together with two optional features to create the ideal environment for optimal crop flow and maximum yield potential. Choose all eight for the ultimate harvest experience. |

Max Flow Trough

Advanced genetics and yield increases have created new demands on the header's crop flow and capacity characteristics. Reducing cob bounce and shatter, as well as efficiently moving trash, are the achievements of the Elite XL Series massive auger trough. |

Variable Auger Positioning

Conditions can differ from field to field, or from morning to night. The ICF auger height adjustment permits easy modification of the auger profile to the trough. You have the power to adapt your machine to your conditions. |

Roller Chains

Aggressive yet gentle feeding, Geringhoff offers the industry's toughest gathering chains. Nine posi-loc lugs create an efficient and durable transfer of the crop from field to stripper plate. Tremendous reliability and unrivaled performance acre after acre. |

Auger Pitch

Elite XL headers offer a swift and efficient transfer of your crop. The varied pitch of the fins gently moves your yield along the outer wings then increases flow as material advances towards the feeder house. The auger's balanced combination of pitch, paddle, size, and speed reduces fluff build up, maximizes your yield and reduces operator fatigue. |

Adjustable Deck Plates

The Elite XL operator has full control over the positioning of the ICF System deck plates. Controlled from within the cab, the deck plate monitor advises current gap settings and allows one touch adjustment on the go. Proven reliability in the toughest conditions over tens of thousands of acres, year after year. |

Poly Angle Adjustment

Geringhoff's poly angle can be easily adapted to your specific needs. Fine tune the angle of your snouts to match crop conditions. Simply turn the adjustment knob to achieve infinitely variable adjustments without the need for tools. |

ICF Sweeper

Rely on the ICF Sweeper to power you through even the toughest conditions when all others have come to a halt. Substantially increase speeds and yield in any condition and reduce your combine hours up to 50%. An integrated design offers a clean, sleek appearance with convenient fore/ aft and up/down adjustments at the touch of a button. Detaches quickly if you prefer but you’ll learn that an ICF Sweeper is the future of corn harvest. |

End Row Augers

Proven to enhance feeding and be more efficient than any end row shield, the optional Elite XL End Row Augers create confidence in any tough or tall crop conditions. In-cab control reduces crop loss as well as bunching and lodging. |

|

|

Folding

Save time by folding instead of hauling Gain capacity and save time with a Rota Disc folding corn head. Today's larger class combines demand the capacity that can only be offered by 12, 16, or 18 row headers. The obvious challenges are trying to move down the road with an oversize implement, or the traditional labor and time intensive procedure of dismounting your header from the combine and having it towed when traveling on roadways. Increase your combine's capacity, save time and make transport safer. Geringhoff offers folding models ranging from four rows to the world's largest 18 row 30" model. With the folding procedure controlled from inside the cab, you'll feel more confident about what's over the next hill or around the next curve while transporting. |

Folding Components

PTO -Both the PTO and auger drives engage with an oversize, spring loaded dog clutch allowing engagement of the drive without slipping or jumping of the drives. Poly Fold - An automated folding sequence allows the poly to fold independently on the inside section to further decrease the transport width. Cab Control - Utilizing existing hydraulic and in cab controls, the entire folding procedure is done from within cab of the combine. |

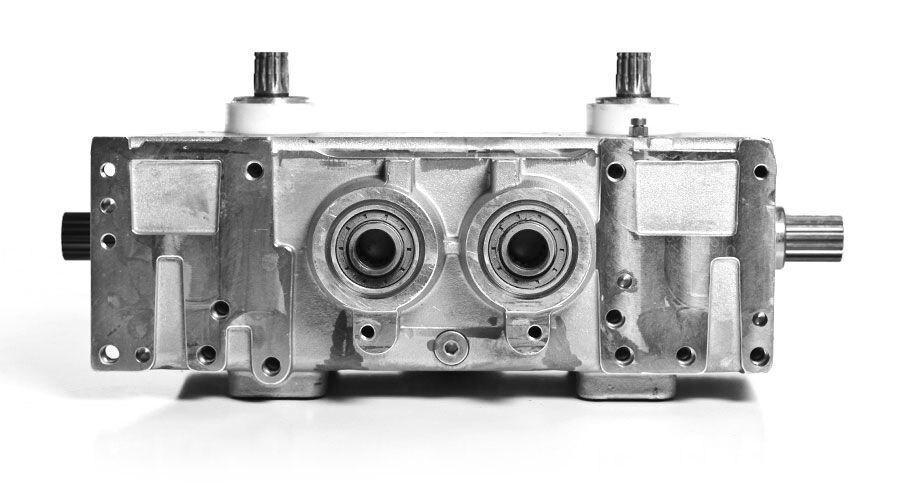

Aluminum Gearbox

Aluminum Gearbox

Powering the Elite XL Series is a maintenance free sealed oil gearbox, which utilizes an internal self adjusting slip clutch to protect all moving parts of the row unit. Designed to be as relentless as the people who use it, these gearboxes are ready for the demanding challenges you send its way. So bring it on. |

Drive Hub

The Geringhoff system eliminates undue stress on the bearings and drive mechanism of each row unit. A positive transfer of power and torque across the entire machine is created with the flex plate row coupler. This design also allows quick and individual removal of any row unit, should service be required. |

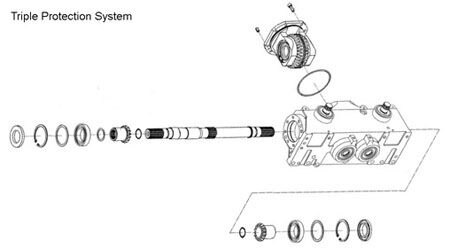

Triple Protection System

Eliminate down time. Spend more time harvesting and less time on repairs and adjustments. This is the goal of the Triple Protection Slip Clutch System. Each row unit features automatic gathering chain tension adjustment, unique beveled sprockets and a slip clutch with an additional double bearing in every row unit gear box. Enter the field with confidence knowing you have triple protection on your side. |

Industry Leading Coverage

Geringhoff offers an industry best comprehensive 12 months parts and labor warranty with all machines. As a bonus, immediately after registering your head with us, we automatically extended your warranty to 24 MONTHS. For additional peace of mind, add Harvest Guard Extended Coverage to your machine and enjoy coverage up to the 60th MONTH. |

Headsight Leveling System

Precise header height control over all types of terrain. At the heart of the Headsight header height control system are flexible poly paddles and reliable electronics. Other systems will dig in to the soil and damage the system when in reverse, but not Headsight. It's design is operator friendly and has been used reliably for decades. |

Sunflower Adaptor

Optional components affordably convert your Geringhoff into an industry leading Sunflower Harvester. Each row receives a cutting knife, ear extensions, and filler plate for maximum yield retention. Add back and side screens to the frame for the ultimate Sunflower harvesting header. |

Combine Adaptors

Versatility is important, that's why our combine adaptors allow the Rota Disc to be easily switched between models or brands. Your header's resale value is maximized by being able to adapt to all combines. |

Model

Rota Disc Elite XL

Category Name

Agriculture

Year

2016

Sale Type

New

Manufacturer

Gerinhoff

Model

Rota Disc Elite XL

Category Name

Agriculture

Year

2016

Sale Type

New

Manufacturer

Gerinhoff

Quantity

0