fendt

Fendt IDEAL

|

Fendt IDEAL combine - More power, more output, more comfort.

The Fendt IDEAL is a machine that works wonders in the shortest harvest windows with uncompromising quality and unconditional reliability. No matter what size combine your land and crops require, regardless of where or what you harvest.

|

|

|

|

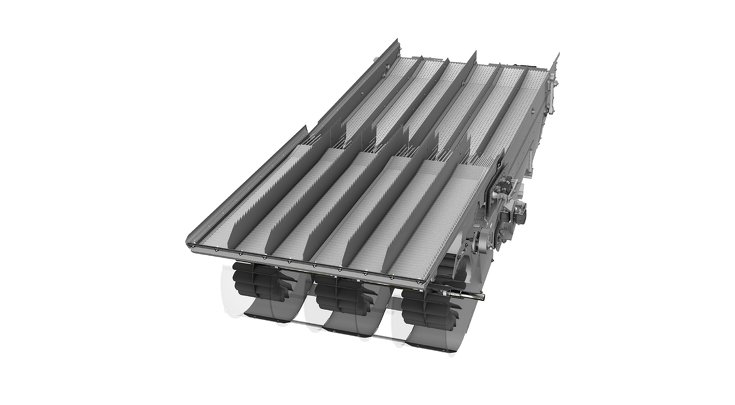

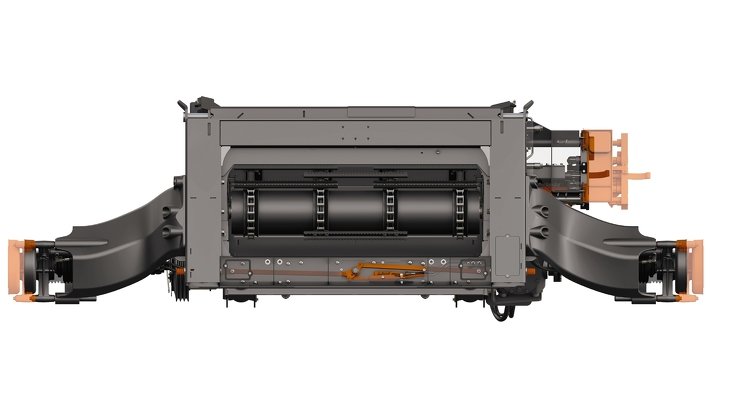

The IDEAL 10 features curved drop steps. Thanks to the curved shape, the heavy grains gather in the lower part of the step, while the laws of physics mean the lighter parts of the crop flow are in the top section. The curved steps provide a wider air outlet, which can significantly increase the air volumes. The 4 curved-step sections of the IDEAL 10 can be easily removed for cleaning. |

|

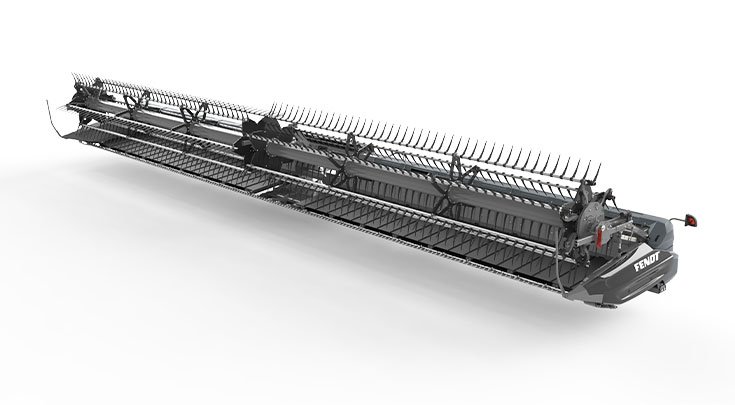

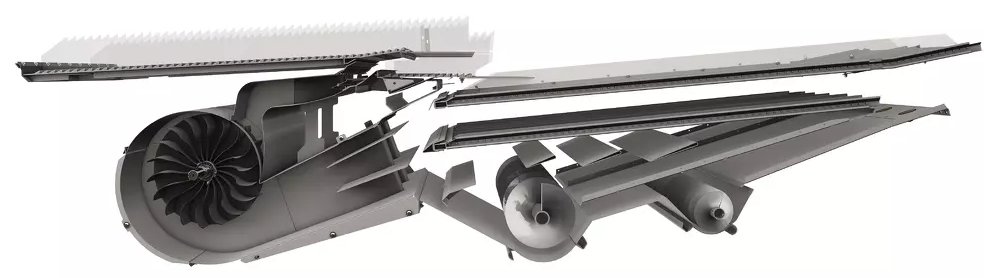

Take it all in with the 9300 Series DynaFlex Headers. Available in widths from 30’ to 50’, the 9300 provides improved feeding with variable – speed gathering belt drive to promote smooth, even and efficient feeding in various conditions. With accumulators that absorb movement and increases response performance to increase the cutter bar coverage and flexibility up to 8” of cutter bar float. With dual mechanical cutter bar drives and a redesigned skid shoe providing enhanced durability for a better footprint on the soil, reducing wear while still providing the low cut height.

|

3300 Command Series Corn Head

3300 Command Series Corn Head

Improve residue management in your fields with the 3300 series corn head, available in chopping and nonchopping models. The stalk rolls are designed with point-to-point contact for increased aggression, while the chopping units will break down the stalks into smaller segments to promote better residue coverage. The slanted deck plate design helps strip the ears from the stalk more aggressively, decreasing butt-loss and kernel loss. To pick up down and tangled corn, the long, shallow snoots can handle even the toughest of harvesting conditions. The 3300 Command series corn head is designed for integration of Reichardt row sending and Headsight header height sensors. |

Fendt Autodock™

Fendt Autodock™

Connecting couldn’t be simpler. Or faster. Or easier. Fendt Autodock™ automatically couples the attachment within 5 seconds, setting standards in terms of ease of use. You don't even have to leave the driver's seat. Once the attachment is added, 4 hydraulic cylinders complete the connection. A hydraulic cylinder in the middle of the feederhouse frame mechanically locks the attachment. At the same time, two couplings push out to connect the PTO drives. AutoDock connects the multicoupler separately to the attachment and the machine. An RFID code, the “Ag tag,” detects the attachment and retrieves the last setting used for that unit. |

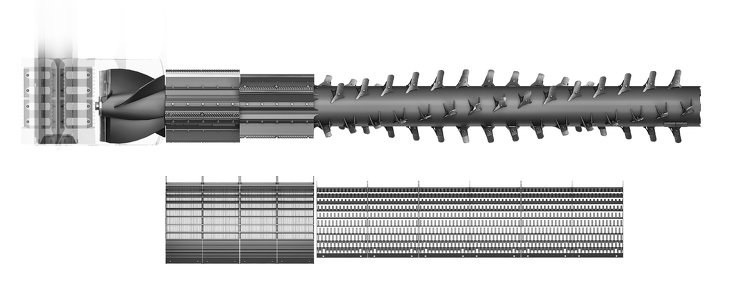

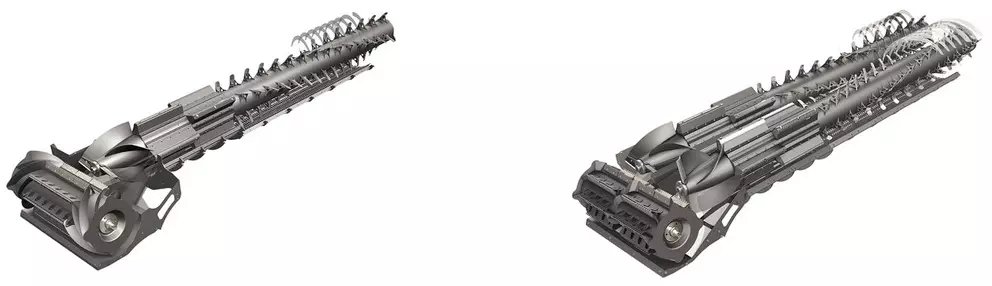

| Superior rotors: Single and Dual Helix. |

Single Helix Dual Helix |

|

All components of the rotors such as the rasp bars and rotor tines are arranged in four rows like a helix. The front part of the rotors consists of 4 rasp bars installed lengthways which thresh the grain. The concaves are available in different configurations for the best results in any application. The clearance between the concave and rotor is hydraulically adjusted up to a maximum of 1.38 inches. The rotor tines are tilted 20° to the rear, which divides the crop into the helix sections and reliably and gently runs it around the rotor. This prevents unexpected load peaks on the rotor and eliminates edges for the product to stick to. |

|

The 24” diameter RotorFeeder feeding drum passes a constant flow of crop to the rotors, guaranteeing optimal transfer and the best threshing results. The RotorFeeder speed is automatically controlled in proportion to the rotor speed – always at 70% of the rotor speed. The speed is adjusted to best match the rotor speed and the large transfer area, maintaining straw quality. The RotorFeeder also uses far less power during this process. |

|

The height of each rotor tine is 5.5” (140mm). Perfectly separating grain without damaging the product too much in too confined a space. In turn you get high straw quality and best threshing at low power. with this simple configuration, the operator only needs to change the rotor speed range and the concave clearance. |

Full-Power Cyclone Cleaning System

|

|

Separate post-threshing Specially designed returns for maximum performance and the best threshing. The product is threshed out by the auger and passed on to the grain pan. This prevents any separating potential being lost at the processor. Threshing occurs between the auger and the interchangeable covers, which can be serrated or smooth depending on the intensity you want. |

|

Superior cleaning The long Startification pan, with six individual sections and high partitions and the long shaker shoes provide for exceptional cleaning in the Fendt IDEAL. Most short straw and chaff is separated from the grain on the first drop between Stratification pan and intermediate floor. The second drop to the top sieve then separates the impurities further. A strong air flow ensures perfect cleaning results. The longest sieves on the market with the integrated partitions mean optimal grain quality. In order to deliver the best results under all conditions, the opening range of the sieves can be electrically adjusted from the cab. |

|

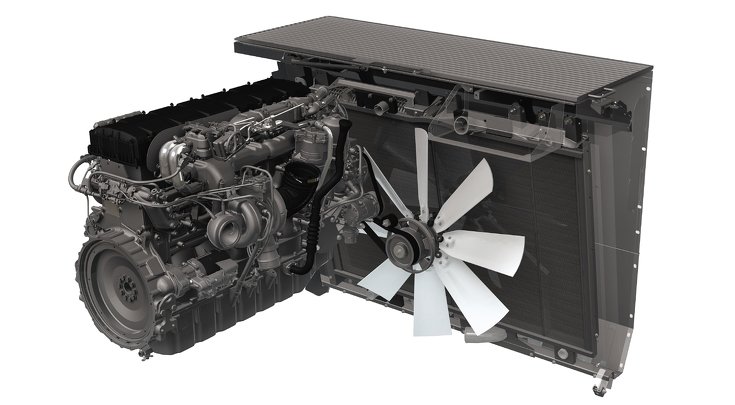

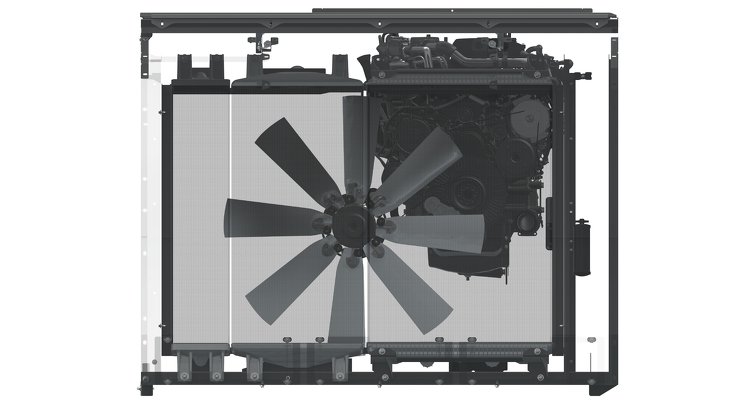

Engines & reversible fan

Perfectly adapted to matching maximum fuel efficiency with the potential output of the Fendt IDEAL. All engines comply with Tier 4 Final emissions and share a well-earned reputation for long service intervals. |

|

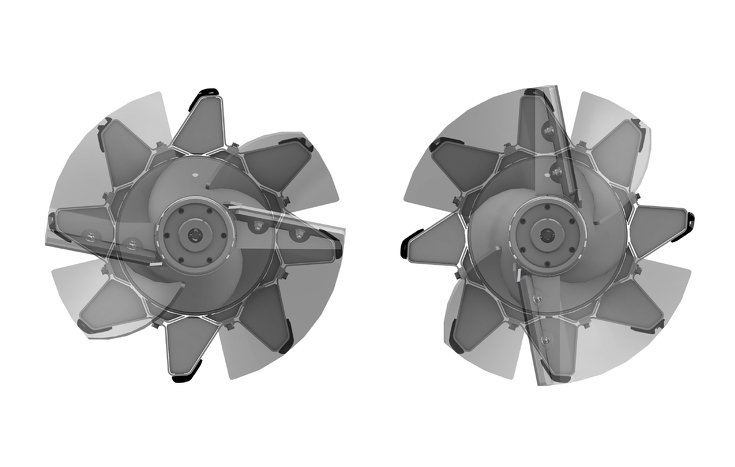

Cooling is a crucial part of ensuring the engines always run efficiently and reliably, so AirSense® Cooling was developed for the Fendt IDEAL. The idea is to provide maximum cooling capacity with minimal cleaning effort. AirSense® Cooling consists of a 37.4” (950mm) reversible fan and a cooling area of 8.8 ft.² (2.7 m²). Dirt and dust never weaken the cooling performance. It’s a system so reliable you can work through an entire season without any manual effort. |

|

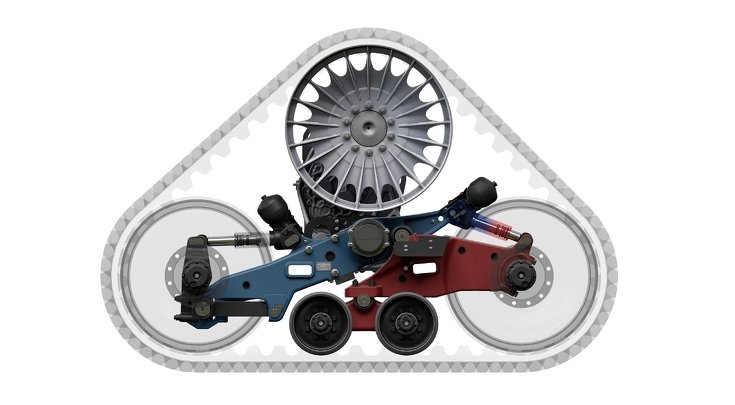

Fendt IDEAL chassis

Developed in the AGCO Center of Expertise for track tractors, three track types with widths of 26” (660 mm), 30” (760 mm) or 36” (910 mm) are available options on all Fendt IDEAL models. The TrakRide system ensures exceptionally low ground pressure. |

|

The IDEAL automatically (and intelligently) switches to 4WD mode independently and intelligently only when the adjusted pressure of the front axle is reached. With the differential lock on, the AWD is permanently on. When you steer the differential lock turns off, and after the maneuver comes back on again, which saves on fuel and protects the axle. |

|

The Fendt IDEAL gearbox

The Fendt IDEAL gearbox offers two gears with a speed range of 0 – 9 mph or 0 – 25 mph (0 – 15 kph or 0 – 40 kph). Fendt MotionShift allows you to shift both gears conveniently during the ride using a button on the armrest. The speed can be easily controlled via the multi-function joystick. The IDEAL's acceleration is linked to the joystick position. Enable the unique Hookup mode on the armrest and the Fendt IDEAL reacts proportionally to joystick movements. This makes light work of coupling attachments. |

| Name | Link |

| Brochure | Download |