Brabus

Case IH Module Express™ Cotton Pickers

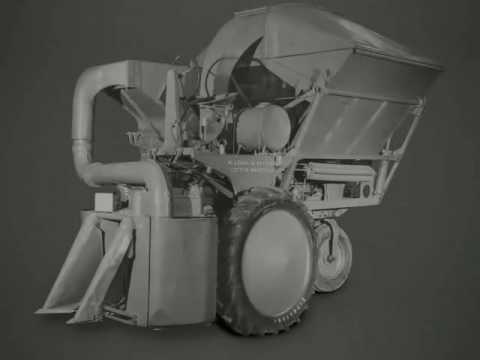

A REVOLUTION IN MODERN COTTON PICKING Introducing a major revolution in modern-day cotton harvesting from Case IH: Module Express™ 635, the first cotton picker with on-board module building. Module Express 635 picks cotton at maximum efficiency and simultaneously builds ginner-friendly cotton modules, dramatically reducing a cotton producer's equipment and labor investment while streamlining the harvest process. | ||||||||

|

Available Models | ||||||||

| ||||||||

|

Features | ||||||||

ENGINEERED WITH THE HIGHEST LEVELS OF QUALITY AND RELIABILITY

| ||||||||

KEY FEATURES:

| ||||||||

AT THE HEART OF THE MODULE EXPRESS 635 IS THE CASE IH MODULE-BUILDING CHAMBERThe module-building chamber is designed to vertically pack a transportable module with no exterior twine or plastic to worry about. A single operator runs one machine that goes from boll to module in one single step. | ||||||||

AUTOMATIC INTELLIGENT AUGER PACKING SYSTEM

| ||||||||

STANDARD "HALF" MODULES

| ||||||||

NO TWINE, NO PLASTIC

| ||||||||

COMPLETE INFORMATION AND CONTROL FROM THE CABAFS PRO 700 MONITORThe AFS Pro 700 Monitor brings enhanced processing speed, reduced overall size, and many other new featured that are all designed to increase productivity, profitability and help maximize your farms' potential. By tracking percent full, module weight and bales per acre, you can easily plan drop-off points around the field that can be conveniently accessed for loading onto module trucks. | ||||||||

Module Monitor The module monitor provides operation status and percent full. In the majority of field length and yield possibilities, the Module Express 625 will be on a field end when the module is between 90 and 125 percent of normal size and ready to unload. This minimizes handling of the modules — the module truck picks up the module right where it is unloaded. A 7-in. (18-cm), flat-screen, color LCD video monitor provides two camera views — in the module chamber and a rear view behind the machine. | ||||||||

TWO-SIDED DROM FOR MAXIMUM PICKING EFFICIENCYBECAUSE COTTON PLANTS HAVE TWO SIDES, SO WHY NOT PICK BOTH? Maximize your yield and profit by picking more cotton from both sides of the row. Get the most through plant pepentration and picking effiency - more than an in-line drum that picks only from one side. EXTENDA-WEAR PLUS SPINDLES The Module Express 625 Cotton Picker features Extenda-Wear Plus™ spindles with a superior barb pattern of three rows of fourteen barbs. The first three barbs in each row are cut at a 30-degree angle to pick efficiently and help the cotton easily move off the spindle during the doffing process. For more efficient picking, the last 11 barbs are cut at a 45-degree angle. Extenda-Wear Plus spindles have 90-micron chrome thickness to provide you with maximum durability. | ||||||||

DESIGNED TO WORK HARD ALL DAY, DAY AFTER DAY, SEASON AFTER SEASONThe designed-for-simplicity service features on the Module Express make it easy to do routine maintenance that helps ensure productivity for years to come. | ||||||||

EXTRA-LARGE TANKS, AUTOMATIC LUBE

| ||||||||

DESIGNED FOR SERVICEABILITY

| ||||||||

EVEN IN TOUGH FIELD CONDITIONS

| ||||||||

THE BALANCE OF POWERA longer chassis also contributes to balance, and combined with the powerful engine, a three-speed hydrostatic transmission and all-wheel-drive, the Module Express 625 can harvest in difficult conditions as easily as it does on dry ground. Along with the high-flotation dual tires, these design features make the Module Express 625 one brawny performer that's remarkably light on its feet. |