Anderson

ID # 15540590

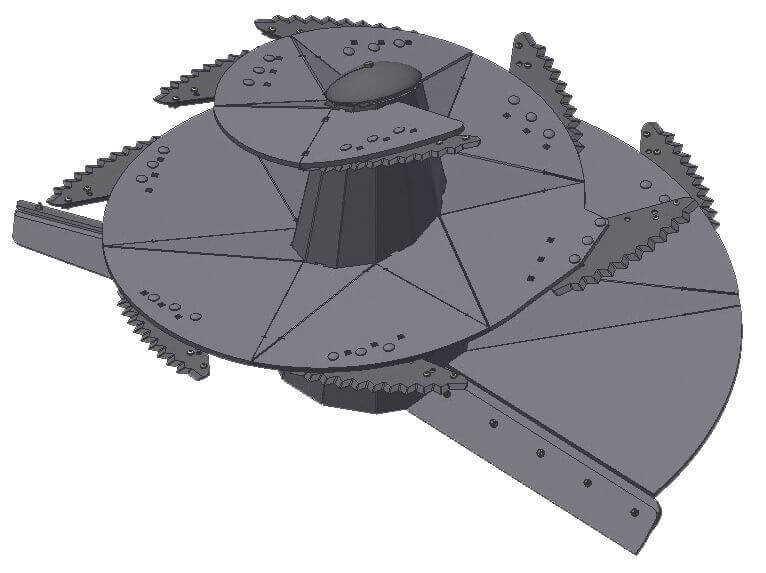

Anderson M600 Self-Propelled Feed Mixer

Call for Price

Overview

Specifications

Videos

Documents

| Anderson’s self-propelled and selfloading M600 mixers have been developed to save time when feeding large herds. These models perform a number of functions including loading and mixing different ingredients and finally distributing the rations accurately using a built-in weighing system. The M600 is a machine powered by a Deutz 6 cylinder engine and automatically driven via hydrostatic traction by the two gear motors placed on the rear wheels. |

|

Features and options |

|

1. Capacity 600 pi3.

2. Reinforced tub fl oor provides longevity of the tub and also to the load cells by equalizing the weight uniformly.

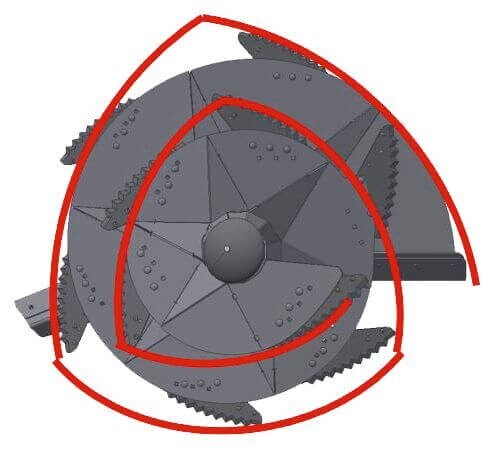

3. TRI-CUT™, auger with 2-position adjustable and reversible knives (10 standard) and 2 sweeping dispensers ensuring a 30% faster and more consistent discharge.

4. Discharge options: rear conveyor.

5. Deutz 217 HP 6 cylinder engine tier IV fi nal.

6. Industry’s fi rst hydraulic TRUE-CUT™ restrictor blades allows the operator to engage and disengage during the mixing process preventing all risks of overprocessing feed.

7. Milling head cutting width 6’ 6’’ (2 m).

8. 4-point scale system.

9. Rolled side walls (not bent) for better fl ow of material, avoiding restriction around auger and naturally increased sturdiness. |

Model

M600 Self-Propelled Feed Mixer

Category Name

Agriculture

Year

2020

Sale Type

New

Manufacturer

Anderson

Load Cell

4

Height (B)

3 m (10' 5")

Length (A)

10,3 m (34' 5")

Machine Weight

14 000kg (30 864 lbs)

Number Of Auger

2

Drive Line Security

Shear bolt

Standard Knives Per Auger

10

Capacity With 12" Extension

16,9 m3 (600 ft3)

3 Availabe Rotation Speed For The Auger

De 0 à 60 RPM

Model

M600 Self-Propelled Feed Mixer

Category Name

Agriculture

Year

2020

Sale Type

New

Manufacturer

Anderson

Quantity

0

Load Cell

4

Height (B)

3 m (10' 5")

Length (A)

10,3 m (34' 5")