Scag

Derette Mini Skid Steer Loader XC1100

|

1、All core components use world-renowned brands 2、Unparalleled safety design 3、Extremely convenient maintenance 4、Design aesthetic that balances appearance and performance 5、More comprehensive configurations:counterweight, bucket cutting edge, fire extinguisher, and instruction manual bucket |

Derette XC1100 Mini Skid Steer Loader – Now Officially Launched!After extensive research and rigorous testing, the highly anticipated Derette XC1100 Mini Skid Steer Loader is now officially released! Engineered for heavy-duty tasks and challenging working conditions, the XC1100 combines powerful performance, high efficiency, and precise control to deliver a fully upgraded construction experience. |

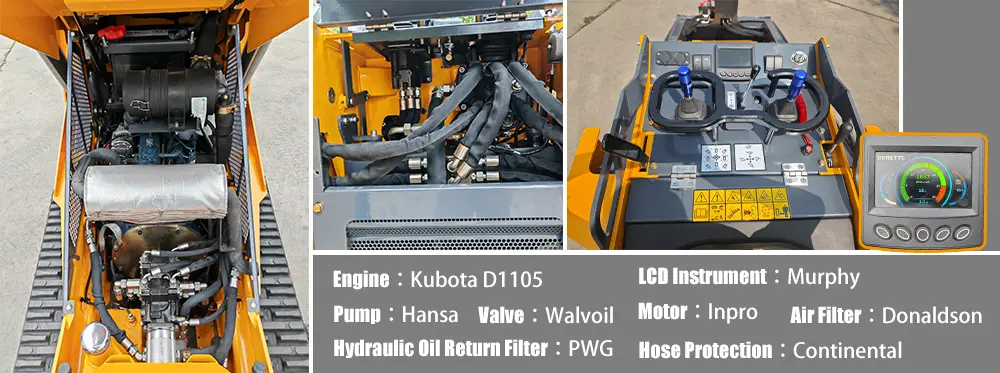

All core components use world-renowned brands

**Pump** : Equipped with the imported Hansa brand pump, renowned for its premium performance that ensures stable operation in fluid transfer and other critical applications. **Valve** : Features the imported Walvoil brand valve, which enables precise control over fluid flow direction and volume, ensuring the efficient operation of the entire hydraulic system. **Motor** : Powered by the Inpro motor (formerly Danfoss), delivering robust and reliable performance to support the equipment's operation. **Air Filter** : Utilizes the imported Donaldson air filter, effectively removing impurities from the air to protect critical components such as the engine and extend their service life. **Hydraulic Oil Return Filter** : Employs the imported PWG hydraulic oil return filter, which provides fine filtration to maintain the optimal performance of the hydraulic system. **LCD Instrument** : Features the same LCD instrument as the Kubota SCL1000, manufactured by the Murphy brand, offering clear and accurate readings for operators to monitor the equipment's status in real-time. **Engine**: Powered by the Kubota D1105 engine, a market-proven powerhouse known for its exceptional performance, high fuel efficiency, and reliability. It delivers consistent and sufficient power to meet diverse operational requirements across various work scenarios. **Hose Protection** : All hydraulic hoses are equipped with Continental-brand (Germany) protective sleeves, which are further wrapped in a layer of wear-resistant black canvas. This dual-layer protection not only safeguards the hoses but also simplifies identification and maintenance. |

Unparalleled safety design

**Custom Molded Seat Cushions**: The ergonomic seat cushions are custom-molded and designed to flip open, allowing operators to inspect the machine's interior for maintenance purposes. **Hose Protection**: All hydraulic hoses are equipped with Continental-brand (Germany) protective sleeves, which are further wrapped in a layer of wear-resistant black canvas. This dual-layer protection not only safeguards the hoses but also simplifies identification and maintenance. **Safety Lockout System** : The right-hand control lever automatically locks when the engine is off, preventing accidental operation and enhancing safety. **Isolated Engine Compartment** : The engine area is fully isolated from the operator compartment, preventing heat transfer and creating a more comfortable working environment while safeguarding sensitive components. **Parking Function** : The equipment is equipped with a parking function. When activated, the loader remains stationary and does not slide or roll when parked on a slope. **The operator standing on the operating platform can see the bucket and attachments in all directions clearly. **In order to prevent the heat of the engine from being quickly transferred to the battery and thus avoid reducing the battery's lifespan, the battery is placed above the engine rather than in front of it. |

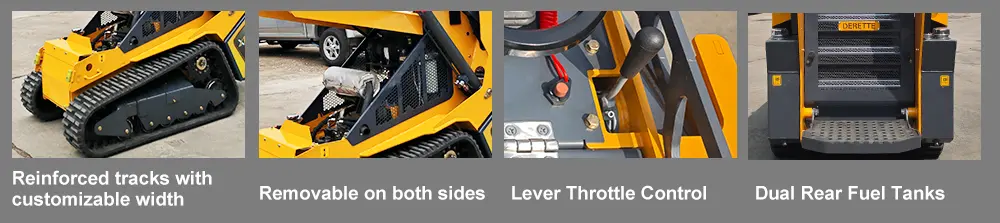

Extremely convenient maintenance

**Tracks** : Designed with reinforced tracks available in two widths, 200mm and 230mm, providing stable support for operation on various terrains. **Body Width** : Available in two widths, 900mm and 950mm, offering flexibility to adapt to different working environments and operational needs. **Easy-Access Loader Sides** : The loader's sides are designed for quick and effortless disassembly, streamlining routine maintenance and inspection tasks. **Lever Throttle Control** : The intuitive lever throttle design offers precise and effortless speed control, allowing operators to maintain optimal performance with minimal effort. **Simultaneous Operation Capability** : The equipment can simultaneously operate high-flow attachments (such as brush cutters and land clearing machines) while raising the boom, enhancing operational flexibility and productivity. **Isolated Engine Compartment** : The engine area is fully isolated from the operator compartment, preventing heat transfer and creating a more comfortable working environment while safeguarding sensitive components. **Dual Rear Fuel Tanks** : The innovative dual-tank design at the rear increases fuel capacity, extending operational runtime and reducing refueling frequency for enhanced productivity. |

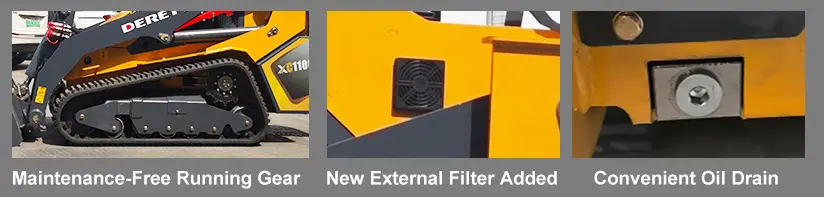

Design aesthetic that balances appearance and performance

**Maintenance-Free Running Gear** : The load-bearing wheels, guide wheels, and tail wheels are designed for lifelong maintenance-free operation, significantly reducing future maintenance costs and workload. **Enhanced Air Filtration** : Features an additional external air filter that improves filtration efficiency, ensuring cleaner air intake for the engine and simplifying maintenance. **Convenient Oil Drain** : An engine oil drain port is located on the left side of the footrest, facilitating easy and efficient oil changes during regular maintenance. **Durable Coupler** : The custom-molded coupler boasts a service life exceeding 2,000 hours, ensuring long-term reliability and consistent performance. |

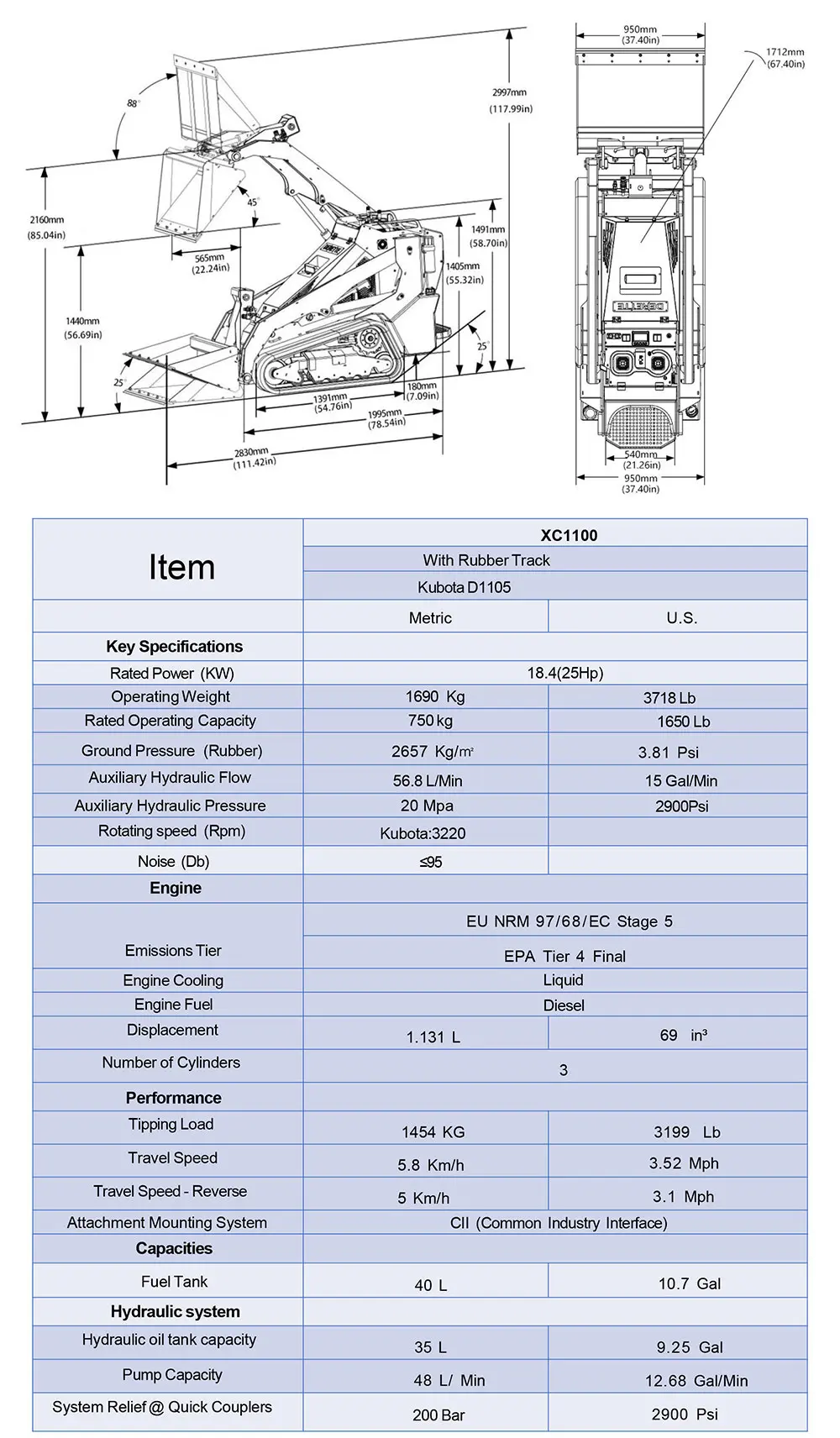

More comprehensive configurations:counterweight, bucket cutting edge, fire extinguisher, and instruction manual bucketTechnical Parameters

|